Environmental, Health, and Safety (EHS) compliance refers to an organization’s adherence to laws, regulations, and standards designed to protect the environment, ensure employee safety, and safeguard public health. It encompasses a broad range of policies, procedures, and systems aimed at minimizing workplace hazards, preventing environmental damage, and maintaining operational integrity. EHS compliance is not merely a legal obligation but a critical component of responsible business operations across industries such as manufacturing, construction, healthcare, and more.

Defining EHS Compliance

EHS compliance involves meeting the requirements set by governmental and international regulatory bodies to ensure safe and environmentally responsible operations. It focuses on three primary areas:

- Environmental Protection: Managing emissions, waste, and hazardous materials to minimize ecological impact and promote sustainability.

- Occupational Health: Protecting workers from workplace hazards such as chemical exposure, ergonomic risks, and other health-related issues.

- Workplace Safety: Implementing measures to prevent accidents and injuries through risk assessments, training, and emergency preparedness.

Compliance requires organizations to align their operations with specific regulations, which vary by region, industry, and operational scope. Failure to comply can lead to legal penalties, operational disruptions, and reputational damage.

Importance of EHS Compliance

EHS compliance is a cornerstone of operational integrity and public trust. Non-compliance can result in significant consequences, including financial penalties, workplace injuries, environmental harm, and loss of stakeholder confidence. Conversely, adherence to EHS standards demonstrates a commitment to ethical practices and operational excellence.

Legal and Financial Implications

Organizations that fail to meet EHS regulations may face fines, lawsuits, or operational shutdowns. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States, the Environmental Protection Agency (EPA), or the Health and Safety Executive (HSE) in the United Kingdom enforce strict penalties for violations. These can range from monetary fines to criminal charges in severe cases, such as incidents resulting in fatalities or significant environmental damage.

Employee and Community Well-Being

EHS compliance prioritizes the safety and health of employees and surrounding communities. By implementing robust safety protocols and health measures, organizations reduce the risk of workplace injuries and illnesses, fostering a culture of trust and accountability. Community-focused EHS practices, such as proper waste management and emissions control, also protect public health and the environment.

Operational Continuity

Compliance helps avoid disruptions caused by accidents, regulatory violations, or permit revocations. By proactively addressing risks, organizations maintain consistent operations and avoid costly downtime.

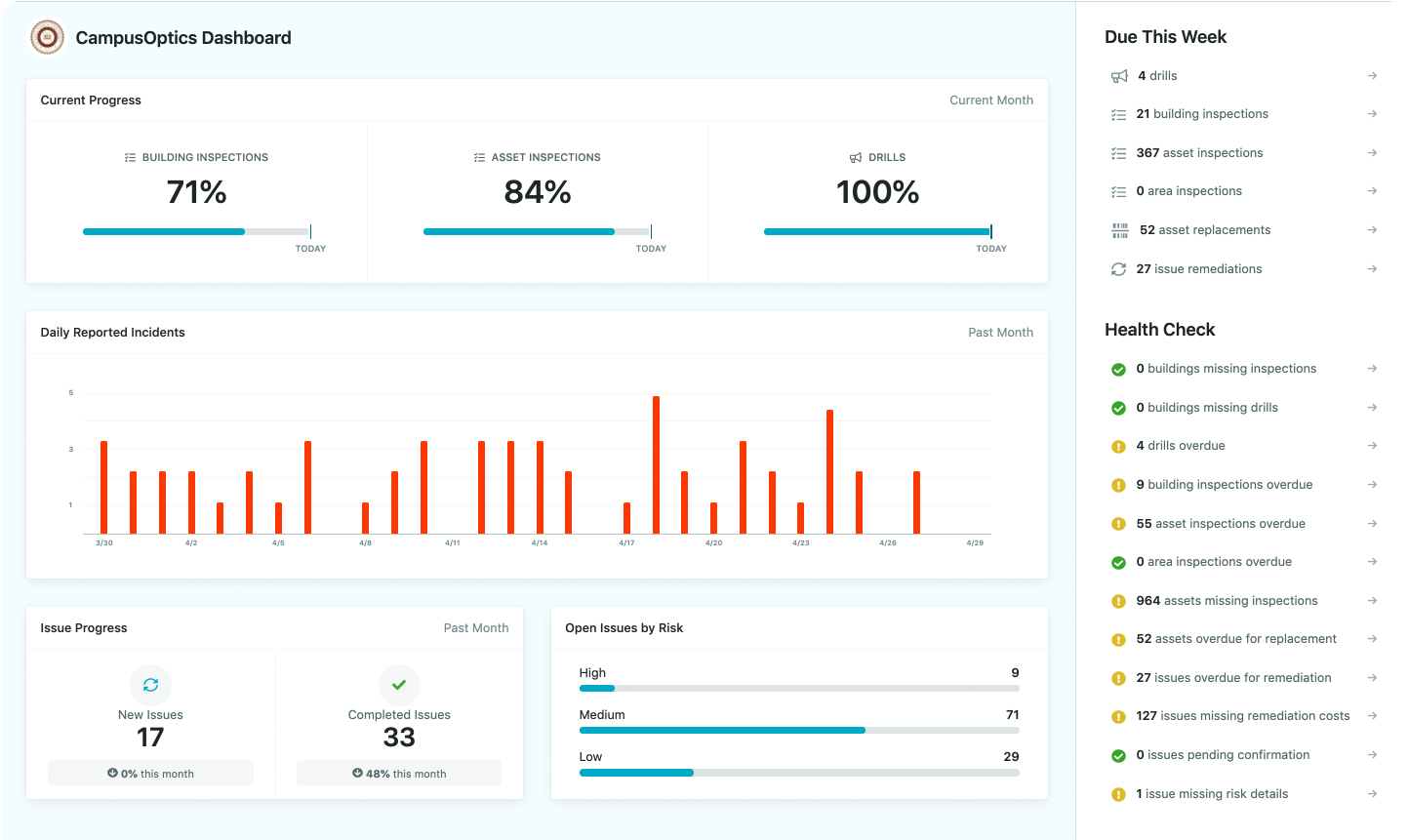

CampusOptics: Our Solution for EHS Compliance in Higher Education

At CampusOptics, we understand the complexities of managing EHS compliance across sprawling university campuses, where risks can emerge in labs, residence halls, or common areas. Our cross-functional EHS platform is designed specifically for higher education, enabling us to streamline compliance with regulations like OSHA and EPA standards. We provide tools to manage chemical inventories, conduct inspections, track incidents, and access emergency plans, all within a single, integrated system. By automating audits and mapping hazards in real time, we help campus safety teams reduce institutional risk and stay prepared for regulatory reviews, ensuring compliance is seamless and sustainable.

Our mobile-first approach keeps pace with the dynamic schedules of EHS professionals. With our iOS and Android apps, we empower users to scan barcodes on hazardous waste containers, capture photos or videos of potential issues, and log notes via talk-to-text while moving across campus. Our interactive mapping feature visualizes safety assets like AEDs or chemical storage locations, enhancing emergency response and compliance reporting. While initial setup may require some customization, our turnkey implementation gets campuses operational in weeks, supported by ongoing service to adapt to evolving needs. We’re committed to simplifying EHS compliance, fostering safer campuses without unnecessary complexity.

Key EHS Regulations and Standards

EHS compliance is governed by a complex framework of regulations and standards, which vary by region and industry. Below are some of the most prominent regulatory frameworks:

Occupational Safety and Health Administration (OSHA)

OSHA, a U.S.-based agency, sets and enforces workplace safety and health standards. Key requirements include:

- Hazard communication to inform employees about chemical risks.

- Fall protection for construction and high-risk environments.

- Machine guarding to prevent equipment-related injuries.

- Mandatory reporting of workplace incidents.

Environmental Protection Agency (EPA)

The EPA regulates environmental impacts, focusing on air and water quality, waste management, and chemical safety. Organizations must obtain permits, monitor emissions, and ensure proper disposal of hazardous materials to comply with EPA standards.

International Standards (ISO)

ISO standards, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety, provide frameworks for organizations to manage risks and improve performance. These standards are voluntary but widely adopted to demonstrate global compliance and sustainability.

European and UK Regulations

In the European Union, regulations like REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) govern chemical safety and product standards. The European Agency for Safety and Health at Work (EU-OSHA) supports workplace safety, while the UK’s HSE enforces similar standards post-Brexit.

Industry-Specific Regulations

Certain industries face additional requirements. For example, construction companies must adhere to strict fall protection and scaffolding standards, while laboratories manage chemical hygiene and biosafety protocols.

Core Components of EHS Compliance

EHS compliance is built on several foundational elements that address environmental, health, and safety concerns. These components form the basis of effective EHS programs.

Environmental Guidelines

Environmental compliance focuses on reducing the ecological footprint of business operations. Key practices include:

- Controlling air and water emissions to meet regulatory standards.

- Managing hazardous waste through proper storage, handling, and disposal.

- Conserving resources like water and energy to promote sustainability.

- Securing environmental permits and maintaining compliance with reporting requirements.

Health Guidelines

Occupational health measures aim to protect employees from workplace hazards. These include:

- Limiting exposure to harmful substances like chemicals or noise.

- Providing adequate hygiene facilities, such as restrooms and first aid stations.

- Conducting health monitoring, such as respiratory or hearing tests, in high-risk environments.

- Implementing disease prevention measures, including vaccinations or infection control.

Safety Guidelines

Workplace safety focuses on preventing accidents and injuries. Essential practices include:

- Conducting regular hazard identification and risk assessments.

- Providing personal protective equipment (PPE) and training employees on its use.

- Establishing safe work practices for high-risk tasks, such as working at heights or with heavy machinery.

- Developing clear incident reporting and investigation processes.

Steps to Achieve EHS Compliance

Achieving EHS compliance requires a structured approach to identify, implement, and maintain regulatory requirements. The following steps outline a practical framework for organizations.

Step 1: Identify Applicable Regulations

Organizations must first determine which regulations apply to their operations. This involves reviewing federal, state, and local laws, as well as industry-specific standards. For example, a manufacturing facility may need to comply with OSHA’s machine guarding requirements and EPA’s waste disposal regulations.

Step 2: Conduct a Gap Assessment

A gap assessment compares current practices against regulatory requirements to identify deficiencies. This process involves internal audits, reviewing historical incident data, and assessing operational workflows. Engaging third-party consultants can provide an objective perspective on compliance gaps.

Step 3: Develop or Update EHS Policies

EHS policies should clearly outline the organization’s commitment to compliance and detail procedures for meeting regulatory requirements. These documents should cover:

- Workplace inspections and audits.

- Hazard control measures.

- Emergency response protocols.

- Incident reporting and investigation processes.

Policies must be tailored to the organization’s operations and updated regularly to reflect regulatory changes.

Step 4: Train Employees

Employee training is critical to translating policies into practice. Training programs should cover:

- Safety protocols for daily tasks.

- Proper use and maintenance of PPE.

- Emergency response procedures.

- Hazard recognition and reporting.

Training should be role-specific, ongoing, and accessible through digital or interactive formats to enhance engagement.

Step 5: Monitor and Optimize

Continuous monitoring ensures compliance over time. Organizations should track:

- Inspection and audit results.

- Incident and near-miss reports.

- Key performance indicators, such as injury rates or training completion.

Regular reviews of policies and procedures, informed by data and regulatory updates, help organizations address emerging risks and improve compliance.

Step 6: Maintain Comprehensive Records

Accurate recordkeeping is essential for demonstrating compliance during audits. Organizations should maintain records of:

- Training sessions and attendance.

- Inspection and audit findings.

- Incident reports and corrective actions.

- Permits and compliance certifications.

Digital tools, such as cloud-based storage and automated reporting systems, streamline recordkeeping and improve accessibility.

Challenges in EHS Compliance

Implementing and maintaining EHS compliance presents several challenges, particularly for organizations with complex or multi-regional operations.

Navigating Evolving Regulations

Regulations frequently change, requiring organizations to stay informed and adapt quickly. Operating across multiple jurisdictions adds complexity, as local, national, and international requirements may differ. Compliance software with automated updates can help track regulatory changes.

Managing Compliance Costs

EHS compliance requires investments in training, technology, and audits. For small and medium-sized enterprises, these costs can be significant. Streamlining processes through digital tools can reduce manual effort and lower expenses.

Ensuring Data Integration

Fragmented data across departments or systems can hinder compliance efforts. Centralized EHS platforms consolidate data, providing visibility into compliance status and facilitating audit preparation.

Maintaining Employee Engagement

Compliance relies on employee adherence to safety protocols. Disengaged workers may overlook procedures or fail to report hazards. Mobile tools and feedback mechanisms can encourage participation and foster a proactive safety culture.

Role of Technology in EHS Compliance

Technology plays a pivotal role in simplifying EHS compliance. Digital tools and platforms enhance efficiency, accuracy, and visibility across compliance processes.

EHS Software Solutions

EHS software centralizes data management, automates reporting, and streamlines inspections. Features include:

- Real-time monitoring of environmental and safety metrics.

- Automated compliance tracking and regulatory updates.

- Digital checklists and audit tools for gap assessments.

IoT and Real-Time Monitoring

Internet of Things (IoT) devices, such as sensors for air quality or equipment status, provide real-time data to identify risks early. These tools enable proactive responses to potential hazards, reducing the likelihood of incidents.

Data Analytics and Reporting

Advanced analytics help organizations identify trends, predict risks, and optimize EHS performance. Automated reporting tools simplify compliance documentation and ensure readiness for regulatory audits.

Best Practices for Sustained EHS Compliance

To maintain long-term compliance, organizations should adopt a proactive and integrated approach:

- Conduct regular risk assessments to identify and address hazards.

- Update policies in response to regulatory changes or incident findings.

- Foster a safety culture through ongoing training and employee engagement.

- Leverage technology to automate compliance tasks and improve data visibility.

- Establish clear roles and responsibilities for EHS management.

Conclusion

EHS compliance is a critical framework for organizations to ensure the safety of their workforce, protect the environment, and meet legal obligations. By adhering to regulations from bodies like OSHA, EPA, and international standards such as ISO, businesses can mitigate risks, avoid penalties, and maintain operational continuity. Implementing a structured approach-through risk assessments, robust policies, employee training, continuous monitoring, and technology-enables organizations to navigate the complexities of compliance effectively. Despite challenges like evolving regulations and resource constraints, proactive management and digital tools can streamline processes and foster a culture of safety and sustainability. A commitment to EHS compliance not only fulfills legal requirements but also supports long-term operational resilience and public trust.

FAQ

What is EHS compliance?

EHS compliance refers to an organization’s adherence to environmental, health, and safety regulations to protect workers, the public, and the environment.

What are the main components of EHS compliance?

The main components include environmental protection (e.g., waste management), occupational health (e.g., exposure controls), and workplace safety (e.g., hazard assessments).

Which agencies enforce EHS regulations?

In the U.S., OSHA and the EPA are primary enforcers. Internationally, agencies like the UK’s HSE and EU-OSHA oversee compliance.

What are the consequences of non-compliance?

Non-compliance can lead to fines, lawsuits, workplace injuries, environmental damage, and reputational harm.

How can technology support EHS compliance?

EHS software, IoT devices, and analytics tools streamline data management, monitor risks, and automate reporting for compliance.

What steps should organizations take to achieve EHS compliance?

Key steps include identifying regulations, conducting gap assessments, developing policies, training employees, monitoring performance, and maintaining records.

Why is employee training important for EHS compliance?

Training ensures employees understand safety protocols, recognize hazards, and follow procedures, reducing the risk of incidents.