If you’ve ever tried to justify an Environmental, Health, and Safety (EHS) initiative to upper management, you’ve probably heard the same question: What’s the return on investment? It’s a fair one. Leadership wants proof that safer workplaces and sustainability programs don’t just feel right, they make financial sense too.

Measuring ROI for EHS isn’t as simple as counting dollars saved after a single project. It’s about connecting the dots between fewer injuries, better compliance, and stronger operations. The good news? You can absolutely quantify those gains. With the right mix of data, context, and a bit of common sense, you can turn safety outcomes into measurable business value.

Why ROI Matters in EHS

Every company says safety is a priority, but when budgets are tight, even essential programs face scrutiny. Leadership often wants proof that investments in Environmental, Health, and Safety (EHS) programs pay off financially, not just ethically. That’s where ROI comes in.

ROI, or return on investment, is a simple way to show how much value your safety initiatives bring compared to what they cost. It transforms “soft” benefits like fewer accidents and happier employees into measurable business outcomes. When calculated well, ROI helps you justify new EHS tools, training programs, or technologies with confidence.

It’s not about putting a price on safety. It’s about showing that doing the right thing for your people and the planet also makes business sense.

Understanding EHS ROI in Simple Terms

In basic terms, ROI measures how much profit or savings you gain from an investment compared to what you spent on it. The formula looks like this:

ROI=(Total Benefits−Total Investment Cost)/Total Investment Cost×100

If your EHS software costs $50,000 and helps you save $150,000 in avoided incidents, reduced downtime, and better efficiency, your ROI is 200%.

But the real value of EHS often goes beyond that equation. Safety investments don’t just prevent accidents; they build efficiency, trust, and resilience. The goal isn’t to overcomplicate the math—it’s to make the invisible benefits visible.

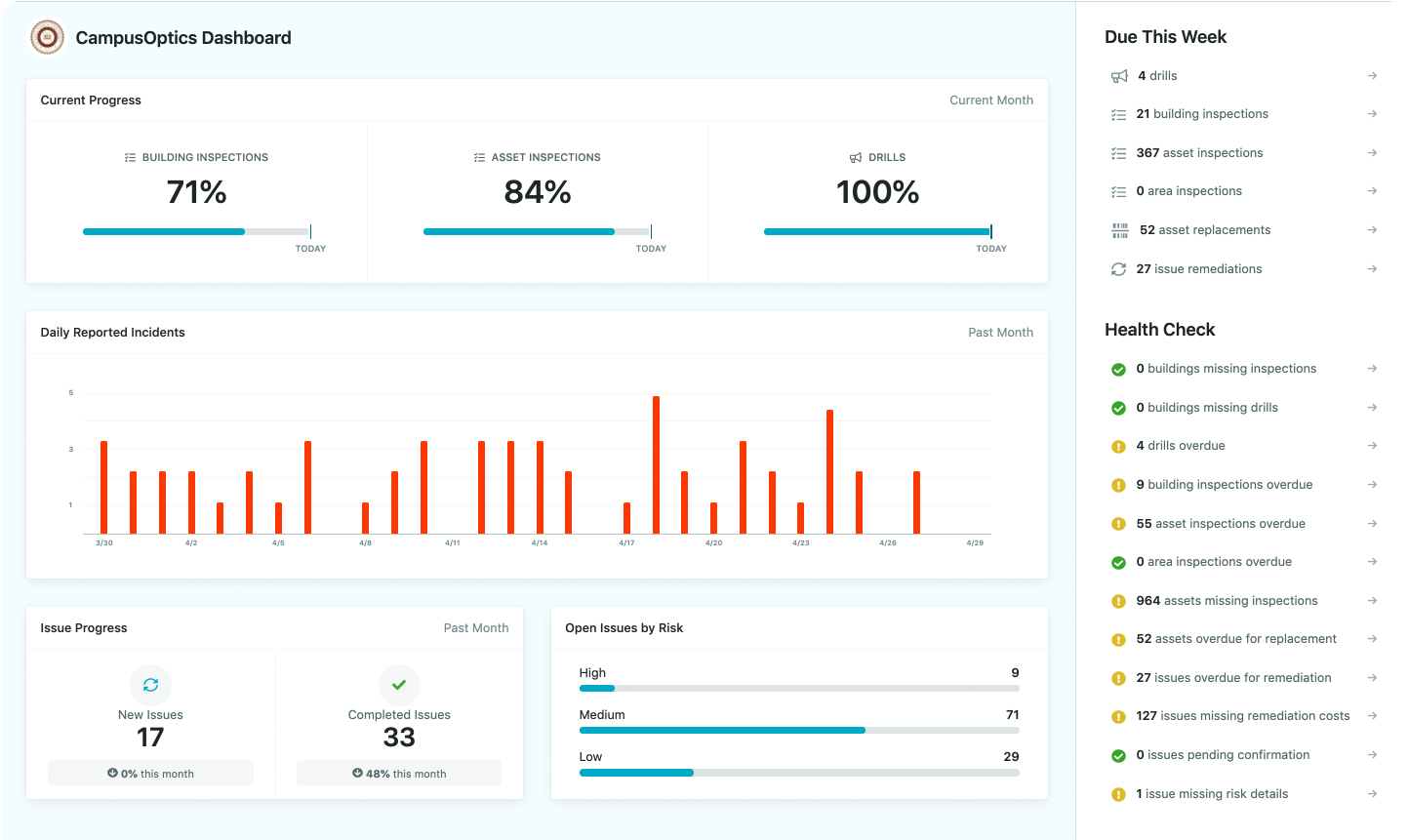

How We See ROI in Practice at CampusOptics

At CampusOptics, we’ve seen firsthand how measuring EHS ROI goes beyond numbers on a spreadsheet. Working with universities and colleges across the country, we help campus safety teams see the financial and operational impact of every improvement they make.

When institutions move from paper forms and disconnected systems to one centralized platform, the results are immediate. Routine inspections take less time. Training compliance jumps because reminders and tracking are automated. Incidents are logged, routed, and resolved faster, which means fewer costly disruptions. Those small gains add up quickly when you multiply them across departments and semesters.

We also believe ROI should include peace of mind. A safer campus protects not only budgets but also people and reputations. After all, behind every report or audit is a student, a lab technician, or a facilities worker who depends on these systems to stay safe. That’s why our approach focuses on both measurable outcomes, like reduced incident costs and higher compliance rates, and the broader value of a stronger safety culture.

Step 1: Identify the Full Cost of Your Investment

Start with clarity on what you’re actually spending. ROI calculations fall apart when costs are underestimated or scattered across departments. Your total investment should include both direct and indirect expenses.

Direct costs are the easiest to calculate:

- Purchase price of EHS software or equipment

- Licensing or subscription fees

- Hardware like tablets or sensors

Indirect costs are the ones people forget:

- Implementation and configuration time

- Employee training and onboarding

- System maintenance and updates

- New personnel or external consultants

For example, if you buy a digital safety management system, the price tag might say $40,000, but once you add training sessions, setup time, and support contracts, the real figure could be closer to $60,000.

Getting this number right sets a realistic foundation for everything else.

Step 2: Quantify Your Tangible Benefits

Now comes the rewarding part: measuring what your investment actually saves or earns. These are your tangible benefits, the ones you can express in dollars.

1. Reduced Incident Costs

Every accident you prevent saves money. OSHA estimates that for every $1 invested in safety, companies save $4–$6 in avoided injury costs. This includes:

- Fewer workers’ compensation claims

- Lower medical and legal expenses

- Reduced downtime from injury investigations

If your company typically spends $100,000 a year on incident-related costs, a 20% reduction through improved EHS programs saves $20,000 right off the bat.

2. Time Savings

EHS software and automation tools eliminate countless hours of manual work. For example, digital inspections and auto-generated reports can save managers dozens of hours per month. Multiply that by their hourly rate, and you’ll have a solid financial estimate.

3. Improved Productivity

A safer workplace leads to fewer disruptions, smoother operations, and higher morale. According to TenForce, companies using modern EHS management systems have reported up to 14% higher productivity and 80% fewer overdue actions.

When employees spend less time dealing with incidents and more time doing their jobs, that’s measurable efficiency you can include in your ROI.

Step 3: Consider the Intangible (But Real) Benefits

Some benefits are harder to express in dollars but equally valuable. These intangible benefits might not appear in the spreadsheet, yet they shape your organization’s long-term success.

- Higher employee morale: People want to feel safe at work. Studies show that 75% of employees are more likely to stay with a company that prioritizes workplace safety, and it directly affects engagement and retention.

- Better reputation: Clients, partners, and regulators respect companies with a strong safety culture. That credibility can open doors to contracts and partnerships.

- Improved compliance: A proactive EHS system reduces audit stress and helps you avoid fines. In 2024, OSHA raised the maximum fine for a single serious violation to over $16,000, so even one avoided penalty counts.

- Cultural impact: When safety becomes part of the company identity, decision-making improves at every level.

You may not be able to attach an exact number to all of these, but they’re part of your real-world ROI story.

Step 4: Calculate the ROI

Once you’ve listed costs and benefits, plug them into the formula.

Let’s say your total annual benefits (cost savings, productivity, etc.) amount to $120,000, and your total investment was $60,000.

ROI=(120,000−60,000)/60,000×100=100%

That means for every dollar invested, you gained one back in value.

But don’t stop at the math. ROI is most persuasive when paired with context. Explain where those savings come from, fewer lost days, faster audits, or lower insurance premiums. The clearer your reasoning, the more credibility your numbers have.

Step 5: Use Real Data Whenever Possible

Estimating benefits is fine to start, but real data is what sells your argument. Pull from:

- Incident logs: Compare before-and-after injury rates.

- Insurance records: Note reductions in claims or premiums.

- Time tracking: Record hours saved through automation.

- Compliance reports: Track fewer violations or audit findings.

If you lack long-term data, use reliable benchmarks from organizations like OSHA or the American Society of Safety Professionals (ASSP). Even a conservative estimate can show leadership that EHS pays for itself faster than expected.

Step 6: Look Beyond the First Year

A common mistake is measuring ROI over too short a period. Many EHS systems pay for themselves within a year, but their true value builds over time. When you take a three-to-five-year view, you start to see how the benefits multiply, incident rates drop as safety culture strengthens, processes become faster as teams adapt, and insurance costs often stabilize or even fall after a few renewal cycles. Safety investments aren’t quick wins; they’re long-term risk management strategies that continue to deliver value year after year.

Step 7: Communicate ROI in the Language of Leadership

Once you’ve calculated your ROI, the next challenge is getting others to see its value. Executives rarely have time for deep technical details, they care about clarity and relevance. Frame your ROI results in plain business terms, showing the financial and operational outcomes that matter most. For instance, you might explain that the new system will save $25,000 in downtime and $15,000 in claims each year, or that it’s projected to deliver a 150% ROI within 18 months while improving audit performance.

The goal is to connect safety investments to the bigger picture. Avoid technical jargon or emotional appeals, and focus on what leadership prioritizes: financial impact, risk reduction, and operational efficiency. When your proposal aligns with broader corporate goals rather than just safety metrics, it’s far more likely to win support.

Real-World Example: Calculating ROI Step-by-Step

Let’s take a mid-sized manufacturing company introducing an EHS software solution.

Investment costs:

- Software license: $50,000

- Implementation and training: $20,000

- Maintenance and support: $10,000

- Total cost: $80,000

Estimated benefits (per year):

- Reduced non-compliance fines: $40,000

- Fewer incidents and compensation claims: $30,000

- Increased efficiency through automation: $20,000

- Better data management and faster audits: $10,000

- Total benefits: $100,000

- Net benefit: $100,000 – $80,000 = $20,000

- ROI: ($20,000 / $80,000) x 100 = 25% ROI in the first year

From year two onward, recurring software benefits often continue while costs drop significantly, making long-term ROI even higher.

Step 8: Refine and Reassess

ROI isn’t a one-time report. It’s something that evolves as your organization grows and conditions change. Keep tracking your results, collect feedback from users, and adjust your approach as you learn more. Over time, these insights reveal which EHS initiatives deliver the most impact, help you forecast future projects with greater accuracy, and build credibility with leadership.

It’s also smart to reassess your ROI each year. Regulations shift, workforces expand, and technology advances. Continuous measurement keeps your EHS investments relevant, effective, and aligned with both safety goals and business priorities.

Tips for More Accurate ROI Calculations

- Be realistic: Don’t overstate the benefits. Conservative estimates make your case more believable.

- Use existing data: Draw from insurance, payroll, or production systems rather than relying on guesses.

- Include intangibles wisely: While not all benefits can be quantified, mentioning them adds valuable context.

- Document assumptions: Clearly note where numbers come from, so others can verify or adjust them later.

- Consider external tools: Resources like OSHA’s Safety Pays calculator can help estimate cost savings from prevented injuries or illnesses.

Common Mistakes to Avoid

Even experienced EHS professionals can misstep when presenting ROI. Here are a few pitfalls to watch for:

- Ignoring hidden costs: Implementation, configuration, and staff training often take more time and money than expected. Be sure to include these in your total investment so your numbers stay accurate.

- Measuring too soon: ROI needs real data to be meaningful. Give your system time to take effect before running calculations, otherwise you risk underestimating its impact.

- Focusing only on savings: Some of the strongest ROI comes from risks you never had to face: fewer fines, less downtime, and improved compliance stability. Savings aren’t always visible, but they’re just as real.

- Failing to tell a story: Numbers alone rarely convince leadership. Pair your data with real examples or outcomes that show how safety investments make a tangible difference.

Remember, the best ROI case blends logic with storytelling. It’s about proving value through both evidence and experience.

The Bigger Picture

EHS ROI isn’t just about crunching numbers. It’s about demonstrating that protecting people, property, and the environment goes hand in hand with running a smarter, stronger business. When you translate safety outcomes into measurable value, you elevate the conversation beyond compliance checklists. It becomes a strategic discussion about resilience, performance, and long-term growth.

Too often, safety is seen as a cost center, a box to tick or a regulation to meet. In reality, it’s one of the most consistent drivers of operational efficiency and employee trust. When incidents go down, morale and productivity rise. When compliance improves, reputations strengthen. These connections are the foundation of a sustainable, future-ready organization.

Understanding the full scope of your costs, tracking the right benefits, and presenting results with clarity helps leadership see what safety professionals already know: EHS isn’t just an expense. It’s an investment in stability, credibility, and the long-term success of both people and business.

Final Thought

Measuring the ROI of EHS investments is about connecting safety to value. The numbers matter, but so does the narrative behind them. When you can show that safer operations lead to stronger performance and happier people, the return becomes undeniable.

Safety doesn’t just protect your bottom line. It strengthens it.

FAQ

What does ROI mean in EHS programs?

ROI, or Return on Investment, measures the financial benefit of your Environmental, Health, and Safety (EHS) initiatives compared to their total cost. It helps you understand how much value your safety programs create through reduced incidents, better compliance, and improved productivity.

Why is it important to measure ROI in EHS?

Calculating ROI helps justify investments in safety programs, technology, or training. It translates the benefits of safer workplaces into business terms that leadership understands, making it easier to secure budgets and demonstrate long-term value.

What should I include when calculating EHS investment costs?

Include both direct and indirect expenses. Direct costs cover software licenses, hardware, and equipment. Indirect costs include implementation time, employee training, maintenance, and any consulting fees.

What are examples of measurable EHS benefits?

Tangible benefits include fewer workplace injuries, lower compensation claims, and saved administrative time. Intangible benefits, though harder to quantify, include stronger safety culture, higher employee morale, and a better brand reputation.

How long should I measure ROI for EHS programs?

A one-year snapshot may not show the full impact. It’s better to assess ROI over three to five years to capture ongoing benefits like improved safety culture, stabilized insurance costs, and sustained productivity gains.