When we talk about workplace safety, a lot of things come to mind: protective gear, warning signs, safety audits, compliance rules. But behind all of that, there’s one thing that holds everything together: training. More specifically, EHS training. If you’ve ever wondered what that actually involves, or why it keeps showing up in compliance conversations, this article is for you.

Let’s take a closer look at what EHS training really means, who needs it, and how organizations can actually make it work.

So, What Does EHS Even Stand For?

EHS stands for Environmental, Health, and Safety. It’s a broad field focused on reducing workplace risks, protecting employees, and minimizing environmental impact. EHS training is the process of teaching people how to stay safe, follow regulations, and respond to emergencies in their specific work environment.

Whether someone works in a lab with chemicals, on a construction site, or in an office, EHS training equips them with the knowledge and tools they need to do their job without putting themselves or others in danger.

Why Companies Need EHS Training

EHS training isn’t optional. In many cases, it’s required by law. Agencies like OSHA (Occupational Safety and Health Administration) in the U.S. and similar organizations around the world set regulations that demand training for a range of industries. But even beyond compliance, there’s a practical reason companies invest in it.

Without proper training, people take unnecessary risks. They make mistakes, overlook hazards, and are slower to respond when something goes wrong. That leads to injuries, illnesses, and lost time. And when things really go off the rails, it could mean lawsuits, fines, or worse.

Good EHS training helps prevent:

- On-the-job injuries and accidents

- Environmental spills or safety violations

- Regulatory fines and legal trouble

- Productivity loss due to downtime or investigations

- High turnover caused by unsafe working conditions

It also boosts morale. When employees feel safe and confident in their roles, they tend to stick around longer and perform better.

What EHS Training Actually Covers

There’s no one-size-fits-all list, but most EHS training programs include a mix of core topics and job-specific content. It depends heavily on the nature of the work, the risks involved, and the regulations in place.

Typical EHS training may include:

- Hazard recognition and risk awareness

- Safe work practices and procedures

- Emergency response protocols

- Incident reporting

- Personal protective equipment (PPE) usage

- Handling hazardous materials

- Fire safety and evacuation

- Ergonomics and injury prevention

- Regulatory compliance basics (e.g., OSHA, EPA)

Different industries may also require specialized training, such as radiation safety, confined space entry, or lockout/tagout procedures.

It’s Not Just About the Content

The content matters, of course. But so does how the training is delivered. This is where many organizations get it wrong. They invest in generic learning modules or outdated videos that employees barely pay attention to. The result? Poor retention and little actual impact.

If the training isn’t accessible, engaging, or relevant, it’s just background noise.

Here’s what actually makes a difference:

1. Make It Job-Specific

Generic safety tips only go so far. A machine operator, a janitor, and a lab tech face completely different risks. The training they get should reflect that.

2. Use Real Examples

People remember stories more than rules. Walking through real-world scenarios or case studies helps employees visualize what can go wrong and how they should respond.

3. Mix Up the Format

Not everyone learns the same way. A good EHS program might include:

- Short videos

- Hands-on simulations

- Mobile-friendly modules

- Group discussions or workshops

- Visual aids and diagrams

4. Make It Ongoing

You can’t train someone once and expect them to remember everything forever. Refresher training keeps safety top of mind and helps organizations adapt to new risks or updated regulations.

Types of EHS Training: When and How It Happens

Let’s break it down by timing and purpose:

Onboarding Training

This is the first wave of training employees receive. It typically covers general workplace safety, emergency protocols, PPE use, and hazard communication.

Role-Based or Department-Specific Training

Once someone is settled into a specific job, they need more focused training that reflects the tasks and risks they handle every day.

Refresher Training

This could be annual, bi-annual, or triggered by events like:

- Changes in laws or procedures

- A near miss or incident

- A scheduled recertification

- New equipment or technology

Supervisor and Manager Training

Those in leadership positions need to know how to model safe behavior, monitor compliance, and support their teams effectively.

Common Challenges (And How to Get Around Them)

Even with the best intentions, many companies struggle to get EHS training right. Here’s why:

1. It Gets Pushed Aside

Training often gets deprioritized in busy organizations. But when safety isn’t baked into the day-to-day culture, things can fall apart fast.

Fix: Make training part of the operational rhythm. Tie it to onboarding, audits, and team reviews.

2. It’s Outdated

Some companies still use training videos from the early 2000s. They may still technically “check the box,” but they don’t engage modern workers.

Fix: Invest in modern content that reflects today’s risks and tech.

3. It’s Disconnected

Training is often handled separately from compliance tracking or incident reporting, which makes it hard to measure results.

Fix: Use a centralized platform that connects training records to safety metrics.

What Makes an EHS Program Effective?

You can tell when a training program is actually doing its job. People stay alert. Hazards are reported before they escalate. Teams know what to do when alarms go off. It doesn’t happen by accident.

Here are a few traits of strong EHS programs:

- Built on real risk assessments: The training is shaped by the actual hazards employees face, not just general safety theory.

- Flexible delivery methods: Online, in-person, mobile – workers can access it when and where it makes sense.

- Clear accountability: Managers can see who completed what, track certifications, and step in if there’s a gap.

- Adaptable to change: As regulations shift, equipment gets upgraded, or job roles change, the training evolves too.

- Integrated into the company culture: Safety isn’t just an annual training day. It’s something discussed in meetings, reviewed in audits, and reinforced on the floor.

Industry-Specific EHS Training Examples

Different work environments come with their own challenges, so it makes sense that training isn’t the same everywhere. Here’s how it often breaks down by industry:

Construction

- Fall protection

- Scaffold and ladder safety

- Trenching hazards

- Tool safety

Healthcare

- Bloodborne pathogen procedures

- Infection control

- Chemical hygiene

- PPE fit and use

Manufacturing

- Lockout/tagout procedures

- Machine guarding

- Noise and air quality standards

Labs and Universities

- Chemical storage and handling

- Emergency eyewash and shower protocols

- Radiation or biohazard safety

- Permit management and inspections

Office Environments

- Ergonomics and desk setup

- Fire evacuation plans

Tools That Make EHS Training Easier

Modern training programs rely heavily on software. And for good reason. It’s hard to manage all the moving parts manually.

A strong EHS platform should help you:

- Assign and schedule training by role or location

- Track completion and certification status

- Store training documents and policies

- Send automatic reminders before expiration dates

- Generate reports for audits or compliance reviews

Some systems also include mobile access, talk-to-text features, barcode scanning, and the ability to attach photos to incident reports or safety inspections.

How We Strengthen EHS Training for Higher Education

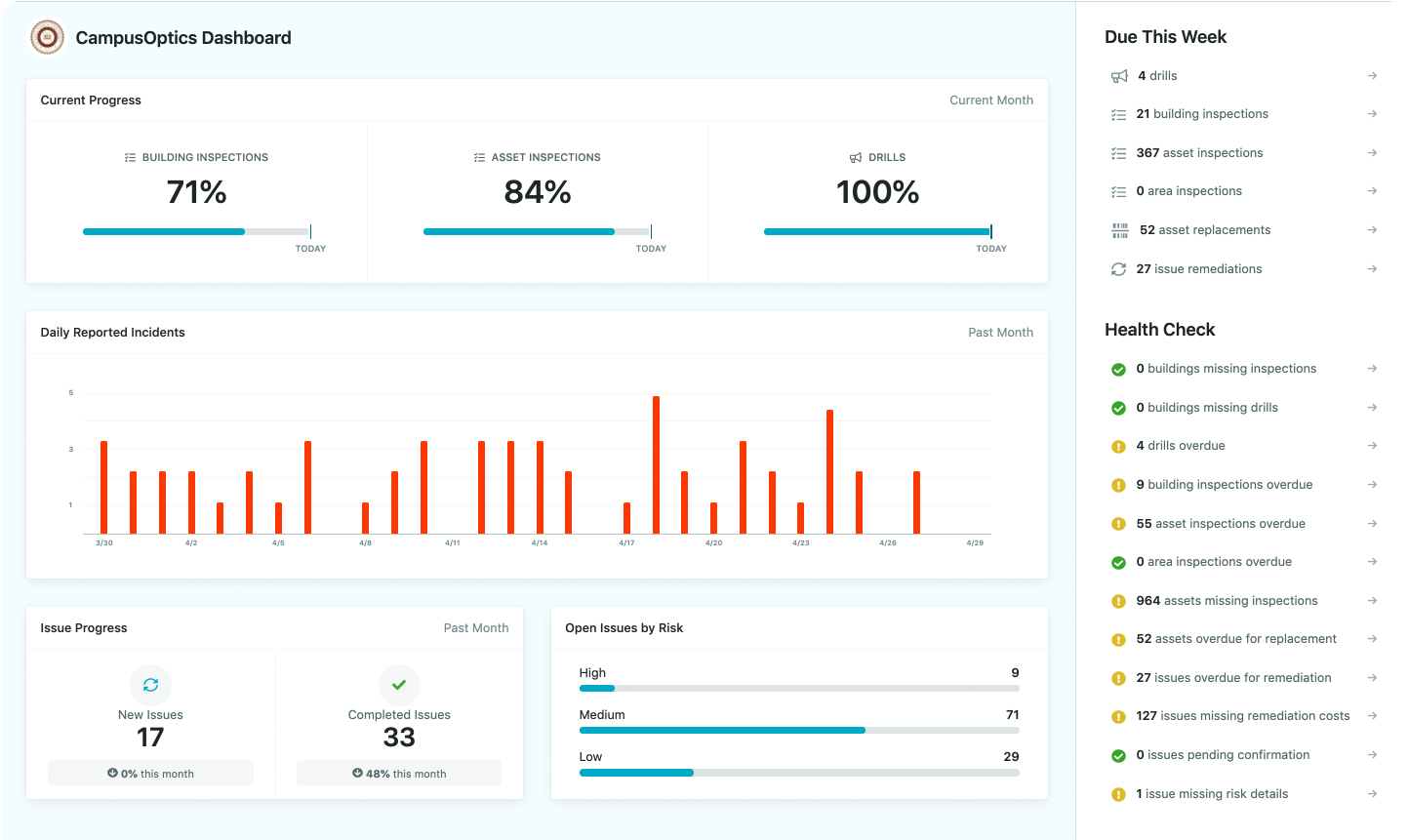

At CampusOptics, we built our platform to make EHS training and safety management simpler and more effective for colleges and universities. We know from experience that safety training isn’t just about compliance; it’s about creating a culture where people know what to do, why it matters, and how to act when something goes wrong.

Our platform helps institutions assign role-specific training, send notifications, and track completions through one convenient dashboard. Because we integrate training with incident records, chemical inventories, inspections, and emergency plans, your programs aren’t based on generic templates – they’re tied directly to the realities on your campus. This gives your teams the right information at the right time, keeps training current, and helps you build a safer, more confident community.

Final Thoughts

EHS training isn’t just a checkbox on a compliance form. It’s a living part of how an organization stays safe, functional, and responsible. When people understand what’s expected of them and why it matters, they show up differently. They speak up when they see something off. They act quickly when there’s a problem. And they become a key part of a culture where safety isn’t an afterthought – it’s just how things are done.

Whether you’re building a new program from scratch or trying to fix one that’s not landing, the approach matters. Tailor the training. Keep it updated. Make it real. And above all, tie it to what’s actually happening in your workplace – not just what looks good on paper.

Frequently Asked Questions

What exactly does EHS training include?

It depends on the job, but most programs cover things like hazard identification, emergency procedures, proper use of PPE, and how to respond to incidents. The goal is to give people the tools to work safely and confidently in their environment.

How often should we conduct EHS training?

Initial training should happen when someone’s hired or moved into a new role. After that, refresher training should be done regularly – at least once a year for most topics. Updates should also happen whenever regulations change, new equipment is introduced, or a safety issue surfaces.

Who is responsible for managing EHS training in a company?

It usually falls under the EHS manager or safety officer, but it really works best when everyone’s involved – from department leads to HR to the workers themselves. Safety is a shared responsibility.

Can EHS training be done entirely online?

Some of it can, especially the foundational material and compliance topics. But for high-risk roles or hands-on tasks, a mix of online and in-person training usually works better. It’s less about format and more about whether the training sticks.

Is EHS training legally required?

In most countries, yes. Agencies like OSHA in the U.S. require specific training depending on the industry. Skipping it isn’t just risky – it can also result in penalties during audits or inspections.

How do we know if our EHS training program is actually working?

You’ll see it in fewer incidents, better reporting, and how confidently people respond when something goes wrong. A good platform can also help track completion rates and spot gaps that need attention.