A chemical safety platform is a digital system designed to manage the risks associated with handling, storing, and disposing of hazardous chemicals in various environments, such as laboratories, industrial facilities, and manufacturing plants. These platforms integrate tools and processes to ensure compliance with regulatory standards, enhance workplace safety, and mitigate environmental risks. By centralizing data and automating critical tasks, they help organizations maintain control over chemical inventories, streamline safety protocols, and reduce the likelihood of accidents. This article explores the purpose, components, and operational mechanisms of chemical safety platforms, drawing on established frameworks from global chemical safety practices.

The Purpose of Chemical Safety Platforms

Chemical safety platforms exist to address the complex challenges of managing hazardous substances in workplaces where chemicals are used, produced, or stored. The primary objective is to minimize risks to human health, property, and the environment. These systems provide structured approaches to track chemical inventories, ensure regulatory compliance, and facilitate employee training. They are particularly relevant in industries like:

- Pharmaceuticals

- Oil and gas

- Agriculture

- Research laboratories

- Where exposure to hazardous substances is a daily concern

The platforms serve as a centralized hub for safety-related information, enabling organizations to monitor chemical usage, manage safety data sheets (SDSs), and maintain transparent records for audits. By leveraging technology, such as cloud-based software or mobile applications, these systems improve accessibility and efficiency, ensuring that safety measures are consistently applied across operations.

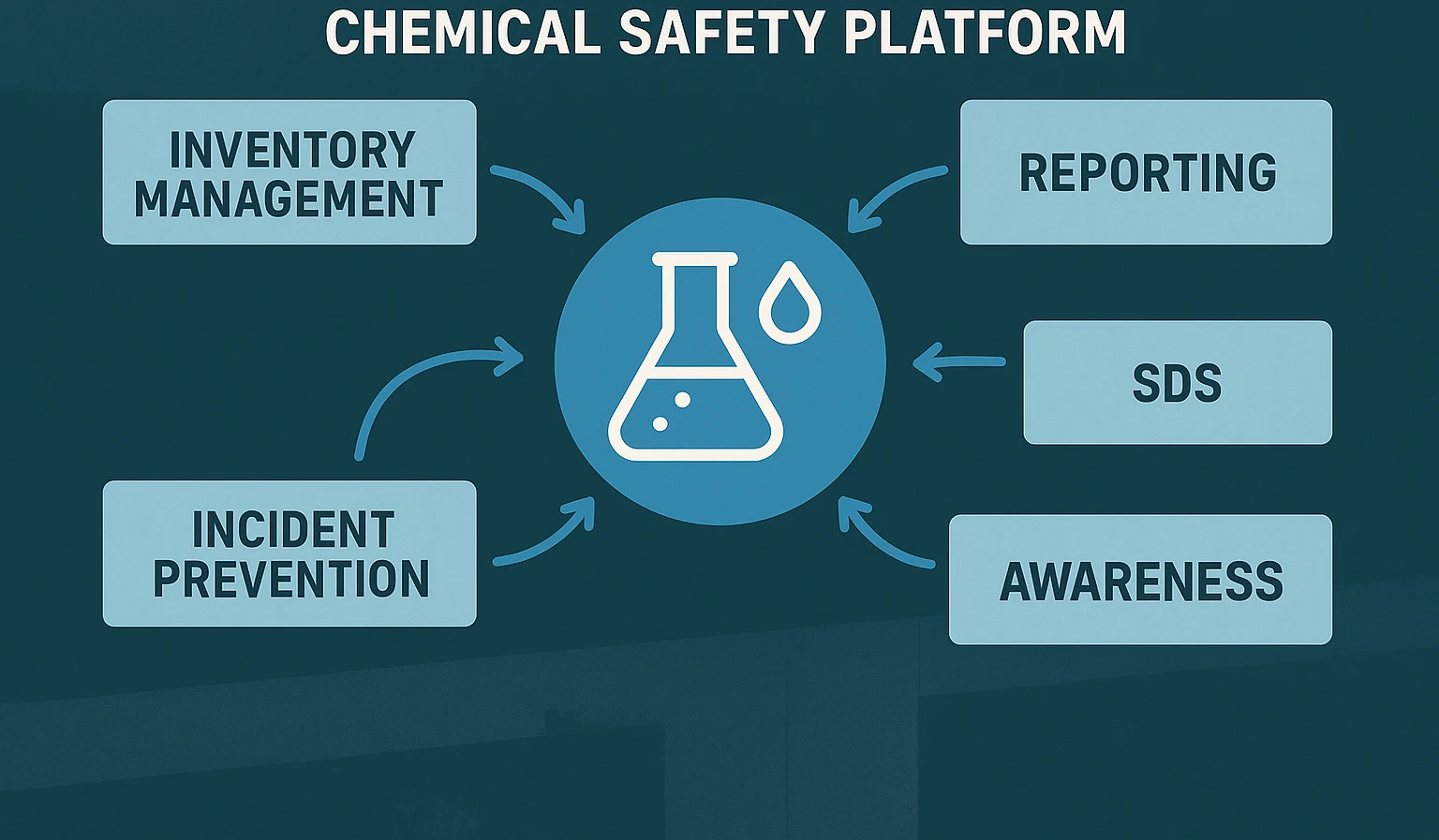

Core Components of a Chemical Safety Platform

Chemical safety platforms are built on several key components that address the diverse aspects of chemical management. These components align with global safety standards and regulations, ensuring that organizations can operate within legal frameworks while protecting their workforce and surroundings.

Chemical Inventory Management

A fundamental feature of any chemical safety platform is its ability to track and manage chemical inventories. This includes monitoring the storage, usage, and disposal of hazardous substances. Platforms typically allow users to catalog chemicals, assign unique identifiers (such as barcodes), and update inventory data in real time. This ensures that organizations have a clear understanding of the chemicals present on-site, their quantities, and their locations.

Inventory management tools also help prevent overstocking or shortages, reducing the risk of expired chemicals or improper storage conditions. Some platforms integrate mobile applications, enabling workers to scan and log chemical data directly from storage areas, enhancing accuracy and accessibility.

Regulatory Compliance and Reporting

Compliance with local and international regulations is a critical aspect of chemical safety. Platforms automate the process of adhering to standards set by organizations like the Occupational Safety and Health Administration (OSHA), the European Chemicals Agency (ECHA), or the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). They generate reports, manage safety data sheets, and ensure proper labeling of chemical containers.

Automated reporting features simplify audits by providing transparent records of chemical usage, storage conditions, and disposal practices. This helps organizations demonstrate compliance during inspections and avoid penalties for non-compliance. Additionally, platforms may include templates for standardized reports, ensuring consistency across documentation.

Safety Data Sheet (SDS) Management

Safety data sheets are essential documents that provide detailed information about a chemical’s properties, hazards, handling procedures, and emergency response measures. Chemical safety platforms maintain digital databases of SDSs, making them easily accessible to employees. These databases ensure that workers can quickly retrieve critical information during routine operations or emergencies.

The platforms also track updates to SDSs, ensuring that the most current versions are available. This is particularly important when regulations change or new hazards are identified. By centralizing SDS management, platforms reduce the risk of outdated or missing information, which could lead to unsafe handling practices.

Risk Assessment and Incident Prevention

Chemical safety platforms facilitate risk assessments by analyzing the properties of chemicals and their potential interactions. They identify hazards such as flammability, toxicity, or corrosivity and recommend appropriate control measures. Some platforms use predictive analytics to flag potential risks, such as incompatible chemical combinations that could lead to explosions or toxic byproducts.

Incident prevention is further supported through features like automated alerts for improper storage conditions or expired chemicals. By integrating risk assessment tools, platforms enable organizations to proactively address vulnerabilities before they result in accidents.

Employee Training and Awareness

Training is a cornerstone of chemical safety, and platforms often include modules to deliver and track employee training programs. These modules cover topics such as proper handling techniques, the use of personal protective equipment (PPE), and emergency response protocols. Training content is typically tailored to the specific chemicals and processes used in the workplace, ensuring relevance.

Platforms may also provide tools for scheduling training sessions, tracking completion rates, and issuing certifications. By maintaining records of employee training, organizations can ensure compliance with regulatory requirements and verify that their workforce is equipped to handle hazardous substances safely.

Emergency Response Planning

Effective emergency response is critical in environments where hazardous chemicals are present. Chemical safety platforms support the development and implementation of emergency response plans, outlining procedures for spills, leaks, or exposures. These plans include details on evacuation routes, decontamination processes, and communication protocols.

Platforms may also integrate with monitoring systems to detect chemical leaks or unsafe conditions in real time. By providing clear, accessible guidelines, they ensure that employees can respond quickly and effectively during emergencies, minimizing harm to personnel and the environment.

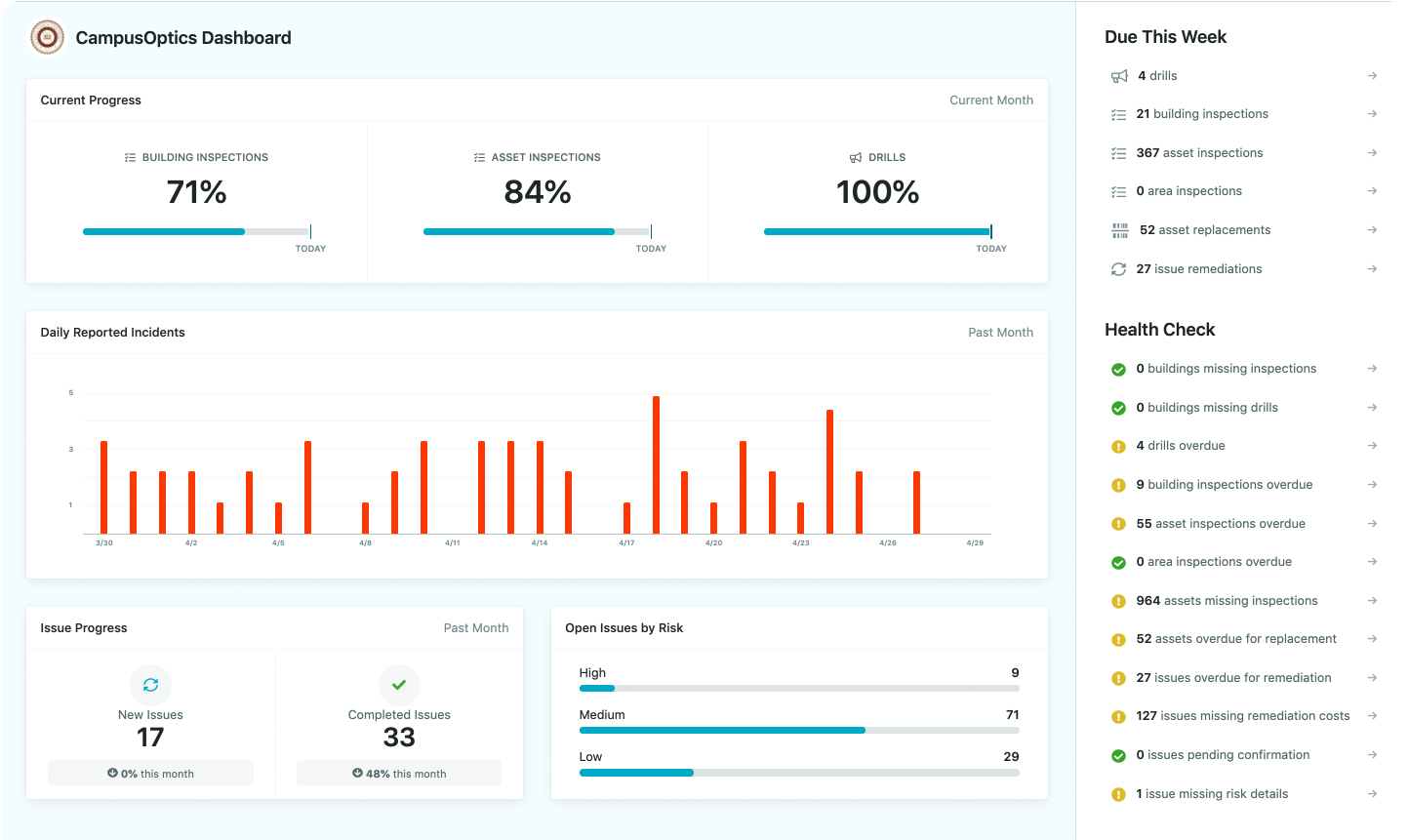

CampusOptics: Our Solution for Chemical Safety in Higher Education

At CampusOptics, we designed our platform to address the unique challenges of managing chemical safety in higher education institutions. Our cross-functional EH&S system integrates seamlessly with campus operations, enabling precise management of chemical inventories, hazardous waste, and safety data sheets while fostering a culture of safety. Built specifically for universities and colleges, our platform centralizes critical data to reduce risks, ensure compliance with regulations like OSHA and GHS, and streamline workflows for EH&S professionals across sprawling campus environments.

Our mobile-first approach sets us apart, offering iOS and Android apps that empower users to manage chemical safety on the go. With barcode and QR code scanning, our platform allows instant access to chemical container details, while in-app photo and video capabilities simplify documentation of inspections or incidents. Features like talk-to-text streamline note-taking, and immediate access to safety data sheets, emergency plans, and floor plans ensures critical information is always at hand. Additionally, our data visualization tools map chemical locations alongside safety assets and incidents, providing clear insights into potential risks across campus facilities.

Key Features of the CampusOptics Chemical Safety Platform

- Tracks chemical inventories accurately: Ensures real-time cataloging and monitoring of hazardous substances across campus facilities.

- Enables mobile management: Provides iOS and Android apps for on-the-go access to chemical data and safety protocols.

- Simplifies container identification: Uses barcode and QR code scanning to quickly retrieve details on chemical containers.

- Streamlines documentation: Supports photo, video, and talk-to-text features for efficient inspection and incident reporting.

- Visualizes campus risks: Maps chemical locations and safety incidents to identify potential hazards across facilities.

- Automates regulatory compliance: Generates reports and manages safety data sheets to align with OSHA and GHS standards.

- Facilitates easy setup and access: Offers turn-key implementation and unlimited user access with customizable permissions.

Integration with Workplace Safety Practices

Chemical safety platforms are designed to complement broader workplace safety practices. They align with regulations such as the Health and Safety at Work Act in the United Kingdom or the Hazardous Substances Regulations in New Zealand. By integrating with existing safety management systems, platforms enhance overall safety protocols without requiring organizations to overhaul their operations.

Personal Protective Equipment (PPE) Management

PPE is a critical defense against chemical hazards, and platforms often include tools to manage PPE inventories and ensure compliance with usage requirements. They may track the availability of items like safety goggles, gloves, and respirators, alerting managers when supplies need replenishment. Additionally, platforms can provide guidance on selecting appropriate PPE based on the chemicals in use, ensuring that workers are adequately protected.

Labeling and Hazard Communication

Proper labeling is essential for identifying chemical hazards and ensuring safe handling. Chemical safety platforms support compliance with labeling standards, such as those outlined in the GHS or the NFPA diamond system used in the United States. These systems use standardized pictograms and codes to communicate hazards like flammability, toxicity, or corrosivity.

Platforms may automate the creation of compliant labels, reducing the risk of human error. They also ensure that labels are updated when new hazards are identified or regulations change, maintaining consistency across the organization.

Applications Across Industries

Chemical safety platforms are versatile tools used in various sectors where hazardous chemicals are prevalent. Their adaptability makes them valuable in diverse settings, from small laboratories to large industrial facilities.

Industrial Manufacturing and Processing

In industries like oil and gas, mining, and chemical manufacturing, platforms manage large-scale chemical inventories and complex processes. They ensure compliance with stringent regulations and provide tools to monitor high-risk operations, such as the handling of flammable or toxic substances.

Research and Academic Laboratories

Laboratories in universities and research institutions handle a wide range of chemicals, often in small quantities. Platforms streamline inventory management, SDS access, and training for lab personnel, ensuring that safety standards are maintained in dynamic environments.

Agriculture and Pharmacology

In agriculture, platforms manage the use of pesticides and fertilizers, ensuring safe storage and disposal to prevent environmental contamination. In pharmacology, they support the handling of active pharmaceutical ingredients, which may pose unique risks due to their potency.

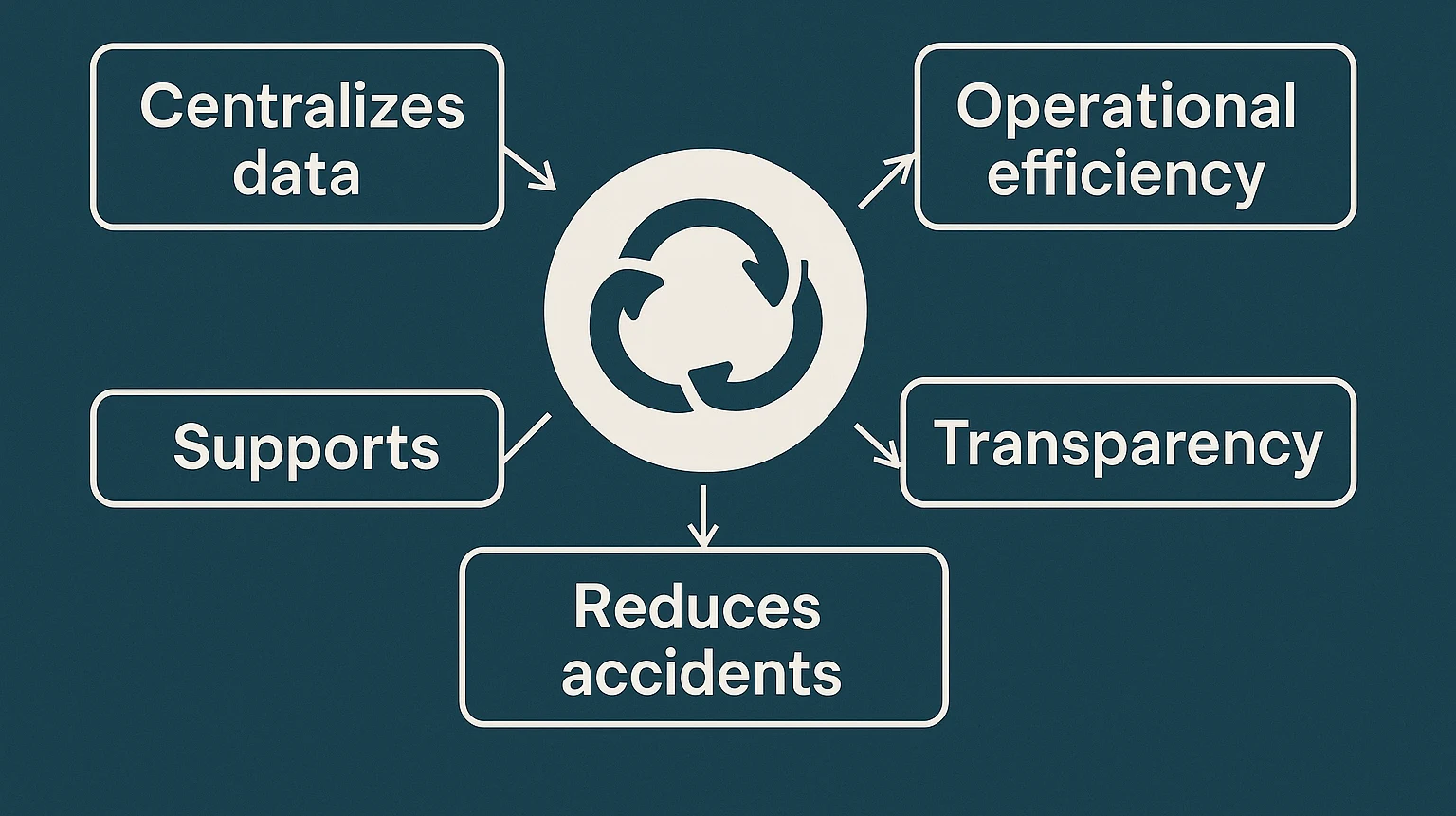

Benefits of Implementing a Chemical Safety Platform

The adoption of a chemical safety platform offers several advantages for organizations.

- Centralizes data and automates processes to reduce administrative burdens

- Improves operational efficiency through streamlined workflows

- Enhances transparency for easier audits and compliance demonstration

- Reduces accident likelihood by providing access to critical information and training

- Supports environmental protection through proper disposal practices

- Minimizes the risk of spills or leaks

Challenges in Chemical Safety Management

While chemical safety platforms are powerful tools, their implementation can present challenges. Organizations may face difficulties integrating platforms with existing systems or ensuring consistent use across departments. Additionally, the initial setup of a platform requires time and resources to catalog inventories, train staff, and configure workflows.

Data accuracy is another concern, as incomplete or outdated information can undermine the platform’s effectiveness. Regular maintenance and updates are necessary to ensure that the system remains aligned with regulatory changes and organizational needs.

Global Standards and Regulatory Frameworks

Chemical safety platforms operate within a framework of global and regional regulations. In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) directive sets standards for chemical management, enforced by the European Chemicals Agency. In the United States, OSHA’s Hazard Communication Standard mandates the use of safety data sheets and proper labeling.

Other regions, such as New Zealand and the United Kingdom, have their own regulatory frameworks, such as the Health and Safety at Work (Hazardous Substances) Regulations and the Health and Safety at Work Act. Chemical safety platforms are designed to align with these standards, ensuring that organizations can operate compliantly regardless of their location.

Future Trends in Chemical Safety Platforms

As technology evolves, chemical safety platforms are incorporating advanced features to enhance their capabilities. Artificial intelligence and machine learning are being used to predict risks and optimize safety protocols. Integration with Internet of Things (IoT) devices allows for real-time monitoring of chemical storage conditions, such as temperature and humidity.

Cloud-based platforms are becoming increasingly popular, offering scalability and remote access. These advancements make it easier for organizations to manage chemical safety across multiple locations while staying compliant with evolving regulations.

Conclusion

Chemical safety platforms are essential tools for managing the risks associated with hazardous chemicals in workplaces ranging from industrial facilities to research laboratories. By integrating inventory management, regulatory compliance, safety data sheet management, risk assessment, employee training, and emergency response planning, these platforms provide a comprehensive approach to ensuring safety and compliance. They streamline operations, enhance transparency, and reduce the likelihood of accidents, protecting both human health and the environment. Despite challenges such as integration and data accuracy, the adoption of these platforms aligns with global regulatory frameworks and leverages emerging technologies like AI and IoT to improve functionality. As industries continue to handle complex chemical processes, chemical safety platforms will remain critical for maintaining safe, compliant, and efficient operations.

FAQ

What is a chemical safety platform?

A chemical safety platform is a digital system that manages the risks associated with handling, storing, and disposing of hazardous chemicals, ensuring compliance and safety.

How does a chemical safety platform improve workplace safety?

It provides tools for inventory management, regulatory compliance, employee training, and emergency response, reducing the risk of accidents and exposure.

What industries benefit from chemical safety platforms?

Industries such as manufacturing, agriculture, pharmacology, and research laboratories use these platforms to manage chemical hazards effectively.

How do chemical safety platforms ensure regulatory compliance?

They automate reporting, manage safety data sheets, and ensure proper labeling, aligning with standards like OSHA, GHS, and REACH.

What role do safety data sheets play in these platforms?

Safety data sheets provide critical information about chemical hazards and handling procedures, stored digitally for easy access and updates.

Can chemical safety platforms prevent environmental harm?

Yes, they facilitate proper storage and disposal practices, reducing the risk of spills and contamination that could harm ecosystems.

Are chemical safety platforms customizable for different workplaces?

Most platforms are adaptable, allowing organizations to tailor features to their specific chemical inventories and operational needs.