In the world of workplace operations, few roles carry the weight of balancing human well-being with environmental stewardship quite like that of an Environmental Health and Safety (EHS) manager. This position sits at the intersection of regulatory demands, operational efficiency, and risk prevention. At its core, an EHS manager oversees systems designed to protect workers from harm while ensuring that business activities align with broader ecological standards. It’s a role that demands vigilance, as oversight lapses can lead to immediate dangers or long-term consequences for both people and the planet.

Organizations across sectors like manufacturing, construction, and energy rely on these professionals to navigate a patchwork of rules that govern everything from chemical handling to emergency preparedness. Without such guidance, even routine processes can spiral into hazards. The EHS manager doesn’t just enforce rules; they build frameworks that embed safety into the fabric of daily work. This involves everything from initial policy drafting to ongoing audits, creating a buffer against the unpredictable elements of industrial life.

As industries evolve with new technologies and shifting climates, the scope of this role expands. What was once focused on basic compliance now includes proactive measures against emerging threats, like those from digital monitoring tools or sustainable material sourcing. Understanding this position means grasping how it influences not only immediate safety but also an organization’s reputation and longevity.

The Foundations of EHS Management

Environmental Health and Safety management forms the backbone of modern organizational practices, aiming to shield both employees and ecosystems from undue risks. This discipline traces its roots to early industrial eras when unchecked operations led to widespread incidents, prompting the need for structured oversight. Today, it operates as a systematic approach, integrating policies that address potential threats before they manifest.

At its essence, EHS management involves identifying vulnerabilities in workflows, from material storage to waste disposal. It requires a holistic view, where health considerations-such as exposure to irritants-merge with safety protocols for machinery operation and environmental checks for emissions control. Organizations operating across borders face added layers, as standards vary by region, demanding adaptable strategies that maintain consistency without overcomplicating local adherence.

Core Components of EHS Frameworks

Effective EHS frameworks rest on several interconnected elements. First, there’s the establishment of clear guidelines that outline acceptable practices for handling substances or conducting tasks. These aren’t static documents; they evolve with operational changes, ensuring relevance. Monitoring follows, where regular evaluations track adherence and flag deviations early. Response mechanisms round out the system, detailing steps for addressing breaches, whether through immediate corrections or broader program adjustments.

In practice, these components create a cycle of prevention. For instance, a framework might start with baseline assessments of site conditions, leading to tailored interventions like ventilation upgrades or signage placements. Over time, this builds a record of compliance that not only satisfies regulators but also informs future refinements. The goal remains straightforward: minimize disruptions while fostering an environment where risks are foreseeable and manageable.

Global and Local Regulatory Landscape

Navigating regulations is a defining challenge in EHS management. Local mandates often dictate specifics, such as noise limits or spill containment, while international accords set broader benchmarks for pollutant release. An EHS manager must reconcile these, often by mapping jurisdictional differences into a unified compliance plan. This isn’t merely administrative; it involves interpreting how rules apply to unique operational contexts, like adapting waste protocols for cross-border supply chains.

The interplay between levels adds complexity. A multinational firm might align with global emission targets but tweak them for regional soil protection laws. Staying current requires ongoing review, as updates can shift priorities overnight. Ultimately, this landscape underscores the managerial role’s technical depth, where knowledge gaps can cascade into vulnerabilities.

Defining the Role of an EHS Manager

An EHS manager serves as the central coordinator for all safety and environmental initiatives within an organization. This individual doesn’t just react to issues; they anticipate them, embedding protective measures into core business functions. In essence, they act as a bridge between executive strategy and frontline execution, translating abstract regulations into actionable steps.

The role varies by scale and sector. In smaller setups, the manager might handle hands-on inspections alongside policy work, while larger entities delegate fieldwork to teams under their supervision. Regardless, the focus stays on integration-ensuring safety isn’t an add-on but a seamless part of production lines or office routines. This demands a blend of technical acumen and interpersonal finesse, as the manager often interfaces with diverse groups to align efforts.

Key Responsibilities in Daily Operations

The responsibilities of an EHS manager center on proactive hazard control and regulatory alignment, creating a daily routine that mixes sharp analysis with hands-on implementation and clear communication. At the heart of it all lies the coordination of assessments to spot risks in everything from office ergonomics to lab chemical handling. These aren’t isolated checks; they happen on a regular cycle to pick up on changes, such as how weather might affect outdoor work sites over time.

To give a clearer sense of the scope, here are some core responsibilities that shape an EHS manager’s typical day:

- Conducting risk assessments and safety inspections to identify potential threats in work environments.

- Developing and rolling out health and safety policies tailored to the organization’s specific needs.

- Ensuring ongoing compliance with local, state, and federal regulations through audits and record reviews.

- Coordinating training sessions to build employee awareness of risks and emergency procedures.

- Leading investigations into incidents to uncover root causes and prevent future occurrences.

Policy development takes a prominent spot, with managers crafting guidelines that fit the operation, like rules for protective gear or streamlined reporting after mishaps. Once in place, implementation kicks in through targeted sessions that give staff the tools they need to apply them effectively. Compliance checks eat up a fair chunk of time too, involving site audits and document reviews to catch any gaps early and address them without delay.

Training and Employee Engagement Initiatives

Training forms a key pillar here, structured to build real understanding without bogging people down. Managers put together sessions that zero in on actual workplace weak spots, pulling from on-site examples to make the lessons stick. Formats vary to suit the group, whether it’s in-person workshops or digital modules that work around shift schedules.

Beyond the formal stuff, engagement keeps things moving through open channels for feedback, where near-misses get flagged early to uncover risks that might otherwise slip by. This back-and-forth setup fosters a sense of ownership, making safety feel like a team effort instead of just orders from above. In the long run, it helps embed good practices that cut down on the need for constant oversight.

How EHS Programs Empower Employees

EHS programs are more than just compliance frameworks; they are tools that empower employees to take ownership of their safety and well-being. By embedding clear guidelines and accessible resources into daily routines, these programs foster confidence and awareness across all levels of an organization. Employees gain practical knowledge through targeted training sessions that use real-world scenarios, making safety protocols relatable and actionable. The following key elements highlight how EHS programs actively support and empower employees:

- Practical Training: Hands-on drills, such as spill response or equipment handling exercises, equip workers with the skills to react swiftly and correctly under pressure.

- Accessible Reporting Tools: Anonymous reporting systems for near-misses or hazards encourage employees to voice concerns without fear, fostering a proactive safety culture.

- Mobile Technology Integration: Tools like mobile apps (e.g., CampusOptics) allow workers to log observations, access safety data, or report issues on the go, enhancing their ability to contribute to workplace safety.

- Collaborative Feedback Loops: Involving employees in safety audits or feedback sessions builds a sense of shared responsibility, making safety a collective mission rather than a top-down mandate.

By integrating these elements, EHS programs transform safety from a regulatory requirement into a shared commitment, boosting employee morale, vigilance, and overall engagement in creating safer workplaces.

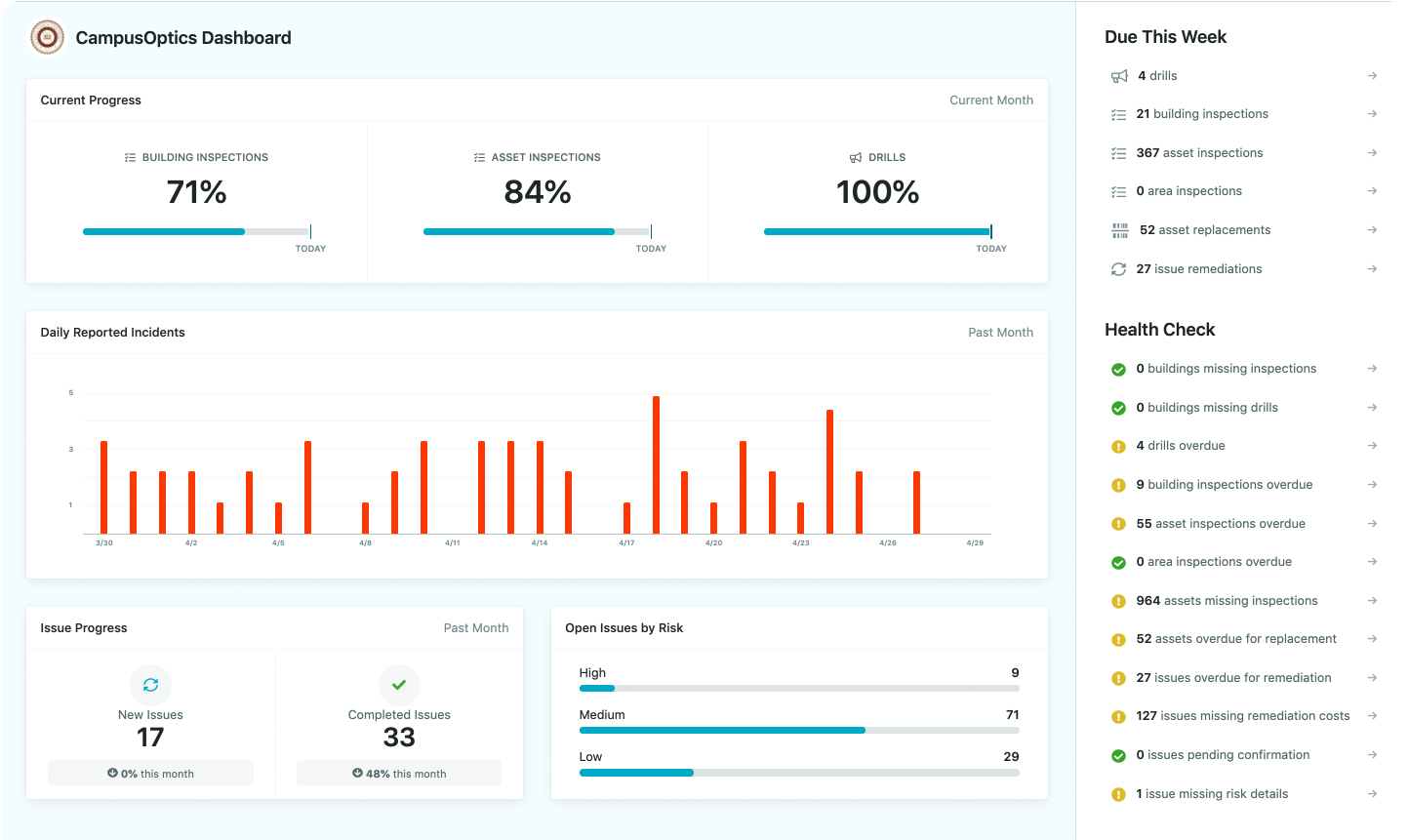

Leveraging Tools Like CampusOptics in EHS Management

At CampusOptics, we designed our platform with EHS managers in higher education in mind, knowing how much ground you cover daily across sprawling campuses. Our cross-functional EH&S solution gives you mobile access via iOS or Android apps to handle chemical inventories, hazardous waste tracking, inspections, and incident logs right from your phone, so you’re not chained to a desk during those critical walkthroughs. Tools like barcode scanning for instant asset details or snapping photos to attach to reports keep your risk assessments sharp and compliant, aligning perfectly with the hands-on oversight that defines your role.

What we hear most from users is how our data visualization features cut through the chaos-mapping out safety assets, incident hotspots, and even public essentials like AEDs or emergency phones with easy imports or on-the-spot GPS logging. Unlimited users with fine-tuned permissions and SSO integration mean you can loop in risk or emergency teams without permission headaches, building that collaborative edge to strengthen safety culture. Plus, our turnkey setup gets you operational in weeks, backed by support that adapts as your needs shift, letting you focus on what matters: proactive hazard control and regulatory peace of mind.

Essential Qualifications and Skills Required

Qualifying for an EHS manager position hinges on a foundation in relevant disciplines, typically built through formal education in areas like environmental studies or occupational health. This background equips candidates with the scientific grounding to grasp hazard dynamics, from biochemical interactions to structural stress points. Advanced learning often follows, deepening insights into specialized topics like toxicology or risk modeling.

Beyond academics, practical exposure matters, gained through roles that involve direct safety oversight. This hands-on time hones judgment under pressure, essential for field decisions. Certifications, while not always mandatory, signal proficiency in standards application, bolstering credibility in competitive fields.

Technical Proficiencies Demanded

Technical skills make up the practical backbone for anyone stepping into an EHS manager role, turning abstract knowledge into tools that handle real-world complexities. It’s about more than theory; these abilities let you quantify risks accurately, whether that’s gauging airborne contaminants or testing structural limits under load. Quick access to regulatory info keeps compliance on track, while crunching data through everyday software helps spot patterns before they escalate into problems.

To break it down, here are some key technical proficiencies that EHS managers rely on daily:

- Mastery of hazard assessment methods, from sampling air quality to evaluating mechanical stresses.

- Proficiency in navigating regulatory databases to cross-check standards and update compliance strategies.

- Skill with analytical tools, including spreadsheets for data trends and simulation software for scenario testing.

- Understanding of emergency response frameworks, such as mapping evacuation paths or containment protocols.

- Expertise in documentation practices to create audit-ready records that hold up under review.

These skills stretch into planning for crises, where knowing the sequence of actions-from alerting teams to securing perimeters-can make all the difference in controlled outcomes. Together, they shift the role from reactive fixes to a forward-leaning stance, where insights from one audit feed directly into stronger defenses elsewhere.

Interpersonal and Organizational Competencies

Interpersonal abilities underpin effective EHS management, starting with clear articulation of complex concepts to non-experts. This involves breaking down regulatory jargon into operational terms during briefings, fostering buy-in. Negotiation skills come into play when aligning departmental agendas, like balancing production speeds with safety pauses.

Organizationally, time management keeps multifaceted duties in check, prioritizing audits amid ad-hoc crises. Attention to procedural details prevents oversights in policy enforcement, while adaptability handles evolving threats. These competencies ensure the role’s influence permeates the organization, not just its immediate sphere.

Typical Projects and Initiatives Led by EHS Managers

EHS managers often spearhead projects that drive long-term improvements, zeroing in on areas like waste reduction or emergency readiness to make safety a built-in part of operations. These initiatives kick off with detailed scoping-comparing what’s happening now to best practices-before moving into step-by-step rollouts that pull in input from across the team. Measuring success comes down to tracking things like fewer incidents or smoother workflows, which then guides whether to scale up or tweak further.

Here’s a rundown of some common projects that EHS managers take the lead on, each one aimed at tackling specific vulnerabilities head-on:

- Developing hazardous waste management programs to handle storage, disposal, and tracking of risky materials.

- Crafting emergency response plans that outline clear steps for crises, from evacuations to containment.

- Building occupational health and safety programs focused on ongoing employee wellness and hazard prevention.

- Creating training initiatives to educate staff on regulations and safe practices in their daily roles.

- Setting up monitoring systems for workplace conditions, including air quality checks and equipment audits.

Emergency drills fit right into this mix as a recurring effort, where managers simulate real-world scenarios-think power failures or spill responses-to gauge how well the team holds up. They build in realistic twists to keep it grounded, and the follow-up reviews always uncover ways to tighten things up, making the whole system more robust over time.

Waste and Hazard Minimization Programs

When it comes to cutting down hazards, these programs start with a full inventory of materials that could pose issues, laying out protocols for everything from secure storage to proper disposal. Managers weave in tracking tech to follow material movement, and they layer on training to stress safe handling that avoids accidental spills or exposures during everyday tasks.

Reaching out to suppliers plays a role too, verifying that incoming goods hit the right safety marks before they even cross the threshold. Wrap-up evaluations look at hard numbers, such as drops in exposure cases, and use that to fine-tune the setup. End of the day, it streamlines the operation so risks get dialed back through smart, intentional choices.

Health Monitoring and Ergonomic Enhancements

Health monitoring efforts involve regular check-ins and sampling to catch low-level exposures before they build up, with managers sifting through data to link patterns back to specific jobs or sites. From there, fixes roll out-like stricter exposure caps or swapping in less harsh alternatives-to keep things under control.

On the ergonomics side, projects dive into workstation reviews to match setups with how bodies actually work, suggesting changes from height-adjustable chairs to better-grip tools that ease strain without slowing down output. Keeping tabs over months shows how well the tweaks stick and what adjustments might boost results further, ensuring the gains hold steady.

Organizational Benefits from Dedicated EHS Oversight

Implementing robust EHS management yields tangible operational steadiness, reducing unplanned downtimes from avoidable incidents. This reliability supports smoother workflows, as teams operate within defined safe parameters. Financially, it curbs potential liabilities tied to non-adherence, preserving resources for core activities.

Employee retention sees indirect gains, as consistent safety measures signal institutional care, lowering attrition from dissatisfaction. Environmentally, controlled practices limit ecological burdens, aligning with stakeholder expectations for responsible conduct. Collectively, these factors enhance adaptability to external pressures, like tightening regulations.

Compliance and Risk Reduction Impacts

Compliance efforts directly mitigate exposure to enforcement actions, maintaining operational licenses intact. By preempting violations through vigilant checks, organizations avoid resource drains on defenses. Risk reduction layers in, as identified vulnerabilities receive targeted interventions, shrinking the probability of cascading failures.

This dual impact fosters a predictive stance, where data from audits informs budgeting for preventive investments. Over cycles, it builds a compliance history that eases interactions with oversight bodies, streamlining approvals for expansions.

Pathways to Entering the EHS Management Field

Entry into EHS management typically unfolds through progressive steps, beginning with foundational positions that offer exposure to safety basics. These starter roles, like coordinator spots, involve supporting audits and basic training, building a practical base. Transitioning upward requires demonstrating reliability in these capacities, often through documented contributions to small-scale improvements.

Formal advancement involves pursuing specialized education or validations that affirm expertise. Networking within industry groups provides visibility, connecting novices to mentors who share insights on role nuances. Persistence pays, as the field values proven track records over rapid climbs.

Building Experience Through Entry-Level Roles

Entry-level engagements immerse individuals in the rhythm of safety operations, from logging observations to assisting in drills. These positions reveal the interplay of theory and practice, highlighting gaps like regulatory interpretation challenges. Seeking varied assignments accelerates growth, exposing one to diverse hazards across departments.

Mentorship within these roles accelerates learning, as seasoned colleagues model decision-making under constraints. Documenting achievements here-such as streamlining a reporting process-creates a portfolio for higher bids, underscoring tangible value added.

Advancing with Professional Development

Advancement hinges on targeted development, where individuals pursue knowledge in niche areas like sustainable auditing. Workshops and simulations sharpen crisis handling, while self-study keeps pace with updates. Peer collaborations, through forums or teams, exchange strategies, enriching perspectives.

Milestones like leading a project mark readiness for escalation, showcasing the ability to integrate oversight into broader functions. This trajectory demands discipline, as the field rewards those who commit to continuous refinement.

Addressing Risks Inherent to the EHS Manager Position

Even as EHS managers safeguard others, their work exposes them to specific perils, particularly during site visits where contact with residues occurs. These encounters, while controlled, carry potential for absorption through skin or inhalation, necessitating layered protections like suited gear and respirators. Adhering to these mitigates immediate threats, preserving personal health amid duties.

Indoor evaluations introduce another vector, with airborne contaminants posing cumulative effects over repeated exposures. Ventilation protocols and sampling tools help quantify and contain these, while scheduled rotations limit duration in affected zones. Desk-bound analysis, though less overt, invites ergonomic strains from prolonged postures, addressed via adjustable aids and movement breaks.

Mitigation Strategies for Occupational Hazards

Mitigation begins with personal inventories, assessing tolerance to common agents and tailoring gear accordingly. Routine protocols, like pre-entry decon, strip away residues before they linger. Health surveillance, through periodic exams, tracks baselines, enabling early interventions for anomalies.

Training in self-protection reinforces habits, from glove selection to decontamination sequences. Collaborating with peers shares load, distributing high-risk tasks. These layers create a personal safety net, allowing focus on organizational duties without undue personal compromise.

Long-Term Wellness and Professional Sustainability

Sustainability demands viewing health as an ongoing priority, integrating wellness checks into career rhythms. This includes balancing fieldwork with analytical phases to avoid overload. Professional networks offer support, discussing coping tactics for stress from incident aftermaths.

Development pursuits keep skills sharp, countering stagnation risks. By modeling these practices, managers reinforce the very standards they uphold, extending benefits beyond the role to personal endurance.

Conclusion

The EHS manager role encapsulates a critical function in contemporary operations, weaving safety and sustainability into everyday decisions. Through vigilant oversight and adaptive strategies, these professionals uphold standards that protect assets and personnel alike. As challenges mount from global shifts, their contributions remain indispensable, guiding organizations toward resilient futures.

Frequently Asked Questions

What distinguishes an EHS manager from other safety roles?

An EHS manager oversees broader environmental and health aspects beyond immediate safety, coordinating compliance across multiple domains unlike more specialized positions focused on single areas.

How does an EHS manager handle multinational compliance?

They map varying regional standards into a core framework, adjusting implementations to fit local nuances while maintaining overarching alignment.

What common projects does an EHS manager lead?

Typical initiatives include hazard audits, emergency plan developments, and training rollouts, each aimed at embedding protections into routines.

Are specific degrees required for EHS management?

While backgrounds in environmental or health fields are common, practical experience and skills often weigh equally in suitability assessments.

How do EHS managers address ergonomic risks?

Through workstation evaluations and adjustments, combined with awareness programs to promote posture and break habits.

What risks do EHS managers face personally?

Exposures during inspections and repetitive strains from documentation, managed via protective gear and ergonomic setups.

Can EHS management improve employee retention?

By creating reliable safe conditions, it reduces dissatisfaction from hazards, indirectly supporting longer tenures.