Regulatory compliance isn’t getting any easier. Whether you’re in healthcare, manufacturing, higher education, or energy, the amount of documentation, safety protocols, and risk management work required today can be overwhelming. That’s where Environmental, Health, and Safety (EHS) software steps in. It’s not just about digitizing forms or ticking off safety checklists. The right solution can bring structure to the chaos, reduce risk, and make compliance something your team can manage with confidence instead of stress.

Let’s dig into how these systems actually help. This article is a straight look at the features that matter, the problems they solve, and what you should expect when bringing one into your workflow.

Why Compliance Needs a Smarter Approach

For most organizations, compliance used to be handled manually. Think spreadsheets, binders full of procedures, or emails flying around with inspection updates. That worked for a while, but with today’s regulations constantly evolving and audits becoming more frequent, that old way of working is now more of a liability than a solution.

Manual tracking leads to delays, missed deadlines, and scattered documentation. And in regulated industries, that’s more than just an inconvenience. It can mean fines, shutdowns, or worse. EHS solutions give teams a smarter, more structured way to stay ahead of those risks.

The Role of Centralized Data in Compliance

One of the core benefits of a solid EHS platform is centralization. Instead of having incident reports in one place, safety data sheets in another, and training logs buried in a shared drive, everything lives in one system.

This matters because most compliance failures aren’t caused by a lack of effort. They’re caused by disorganized information. When data is scattered across departments and platforms, it’s almost impossible to respond quickly during an audit or investigation.

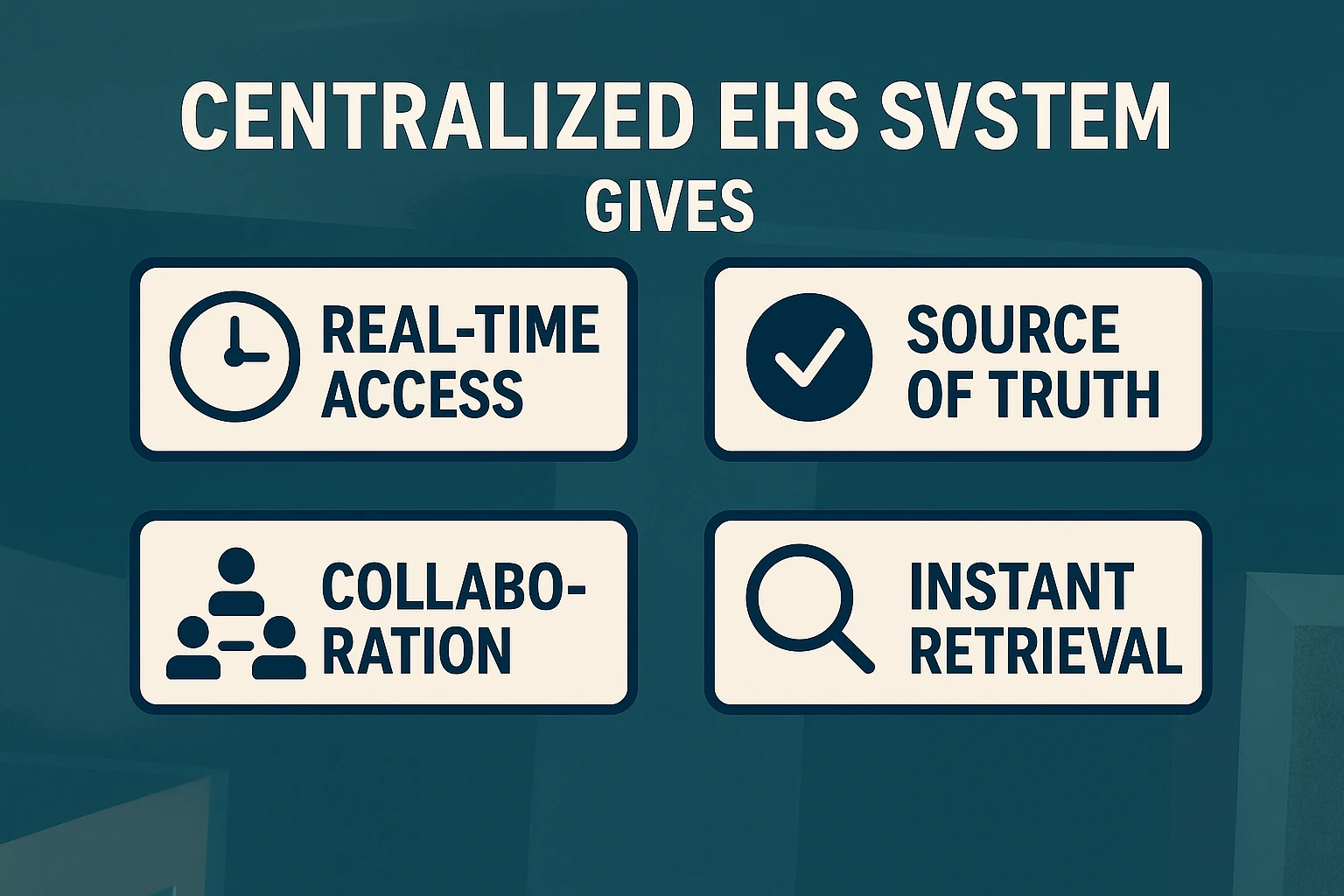

A centralized EHS system gives you:

- Real-time access to compliance documentation

- A single source of truth for inspections, training, and safety protocols

- Easier collaboration across safety, HR, operations, and facilities

- Instant retrieval of documentation when regulators ask for it

Think of it like having your entire safety operation at your fingertips instead of buried across multiple inboxes and folders.

Automation Makes Compliance Easier to Maintain

If you’ve ever had to prepare for an audit by digging through emails, spreadsheets, and shared folders, you know how draining that process can be. It’s not just time-consuming – it’s stressful, especially when you’re trying to meet a deadline and can’t find the right version of a document. EHS solutions ease that burden by automating many of the tasks that used to be manual, repetitive, and prone to error.

Take reporting, for example. Instead of manually compiling data for chemical inventory or incident reports, a solid EHS platform generates them for you using the data your team is already logging as part of their daily work. That alone can cut hours or even days off your reporting cycle.

Automation also touches other parts of the compliance workflow. It helps ensure that incident reports are followed up on, training is assigned and tracked properly, permits are reviewed and renewed on time, inspections don’t fall through the cracks, and every document stays current and version-controlled. You’re not chasing paper trails or relying on someone’s memory to send a reminder – the system handles it.

All of this leads to fewer mistakes, faster response times, and a much more consistent compliance process. And in a world where consistency is key to staying out of trouble with regulators, that kind of reliability makes a real difference.

Monitoring and Risk Management in EHS Compliance

Modern EHS platforms aren’t just digital filing cabinets – they actively monitor conditions and flag risks as they emerge. The combination of real-time data and structured risk assessment tools gives organizations a much sharper edge when it comes to preventing accidents, reducing exposure, and staying compliant.

Why Monitoring Matters More Than Ever

Regulatory compliance is often about response time. When something goes wrong, how quickly you detect it – and how effectively you respond – can mean the difference between a fixable issue and a reportable incident. Monitoring tools in EHS software change the timeline entirely.

Instead of waiting for an inspection or employee report, systems can now alert teams the moment something crosses a defined due date or threshold.

These alerts don’t just help prevent incidents – they also leave a clear digital trail showing that your organization is proactively managing safety, which matters to regulators.

Risk Assessment Moves from Theory to Action

Knowing that something happened is one thing. Understanding why it happened – and how to prevent it next time – is what risk management is all about. Too often, risk assessments are done just to meet requirements. They live in binders, get reviewed annually, and rarely change unless something goes seriously wrong. EHS platforms challenge that model by embedding risk tracking directly into workflows.

Digital tools walk teams through hazard identification, scoring systems, and control planning. They connect incidents to real operational data and flag patterns as they emerge.

With integrated risk management, you can:

- Identify potential hazards using historical trends

- Automatically score risks based on severity and likelihood

- Create and assign mitigation tasks with due dates

- Monitor how risk levels shift as conditions or operations change

This isn’t about increasing paperwork. It’s about bringing visibility to the places where risk hides – and equipping your team to respond before it turns into a compliance issue or safety event.

Integration with Other Systems Makes Everything Work Together

EHS compliance rarely operates on its own. It involves people, equipment, training, and documentation – much of which is managed outside the EHS platform. That’s why integration matters. By connecting EHS software with other internal systems, organizations can reduce manual work, close communication gaps, and maintain cleaner, more accurate records across departments.

HR Systems: Keep Training and Certifications in Sync

EHS platforms that integrate with HR systems can automatically match job roles to required training. This ensures that employees receive the right modules, certifications stay current, and records are easily accessible during audits. It also avoids duplicated data entry between HR and safety teams.

Maintenance Software: Link Safety Issues to Repair Actions

When inspections uncover a broken guardrail or faulty equipment, that issue shouldn’t sit in a report – it should trigger a repair. Integration with maintenance tools lets inspection findings flow directly into work order systems, helping teams act faster and keeping repair logs aligned with compliance requirements.

Document Management Tools: Control Access to Critical Files

Compliance often requires storing and referencing safety manuals, inspection forms, permits, or SDS documents. Connecting EHS software to a centralized document repository helps ensure that teams always access the latest version. It also improves visibility into who viewed or edited key compliance files.

Chemical Inventory Databases: Keep Safety Data Sheets Updated

For organizations managing hazardous materials, having accurate SDS records is critical. Integration with chemical inventory databases helps ensure that EHS platforms automatically reflect real-time updates to product formulations, handling instructions, or regulatory classifications – without manual uploads.

Keeping Up with Changing Regulations

One of the most difficult parts of compliance is staying ahead of evolving laws. Regulations don’t just change between industries – they often shift within regions, agencies, or even job roles. If your internal policies don’t adjust accordingly, you could slip out of compliance without realizing it until an auditor flags the issue.

This is where EHS software becomes a real asset. Many platforms include built-in tools that track changes in regulatory frameworks and compare them against your current workflows. Instead of waiting to find out that your permit process or inspection schedule is outdated, the system flags it for you.

When regulations change, the software can highlight exactly where your existing processes fall short. You might see a warning that a procedure no longer meets updated requirements, or get an alert about a newly required form or checklist. These systems also make it easier to roll out changes across teams by allowing you to update forms and workflows in one place – rather than reworking policies in five different departments.

By automating this kind of visibility and reducing the time needed to react, EHS platforms help organizations avoid last-minute scrambles, missteps during audits, or unintended violations. Staying current becomes a built-in process, not a separate project.

Building a Culture of Accountability

Compliance isn’t just a software problem. It’s also a people problem. EHS solutions don’t just help you meet the rules – they help your team actually understand and own the process.

By making safety data accessible, giving teams tools to report issues, and showing how their work connects to broader goals, these platforms help build a stronger safety culture.

You’re not just managing risk from the top down. You’re empowering the people who are closest to the work to contribute in a meaningful way.

How We Support Compliance Across Higher Education

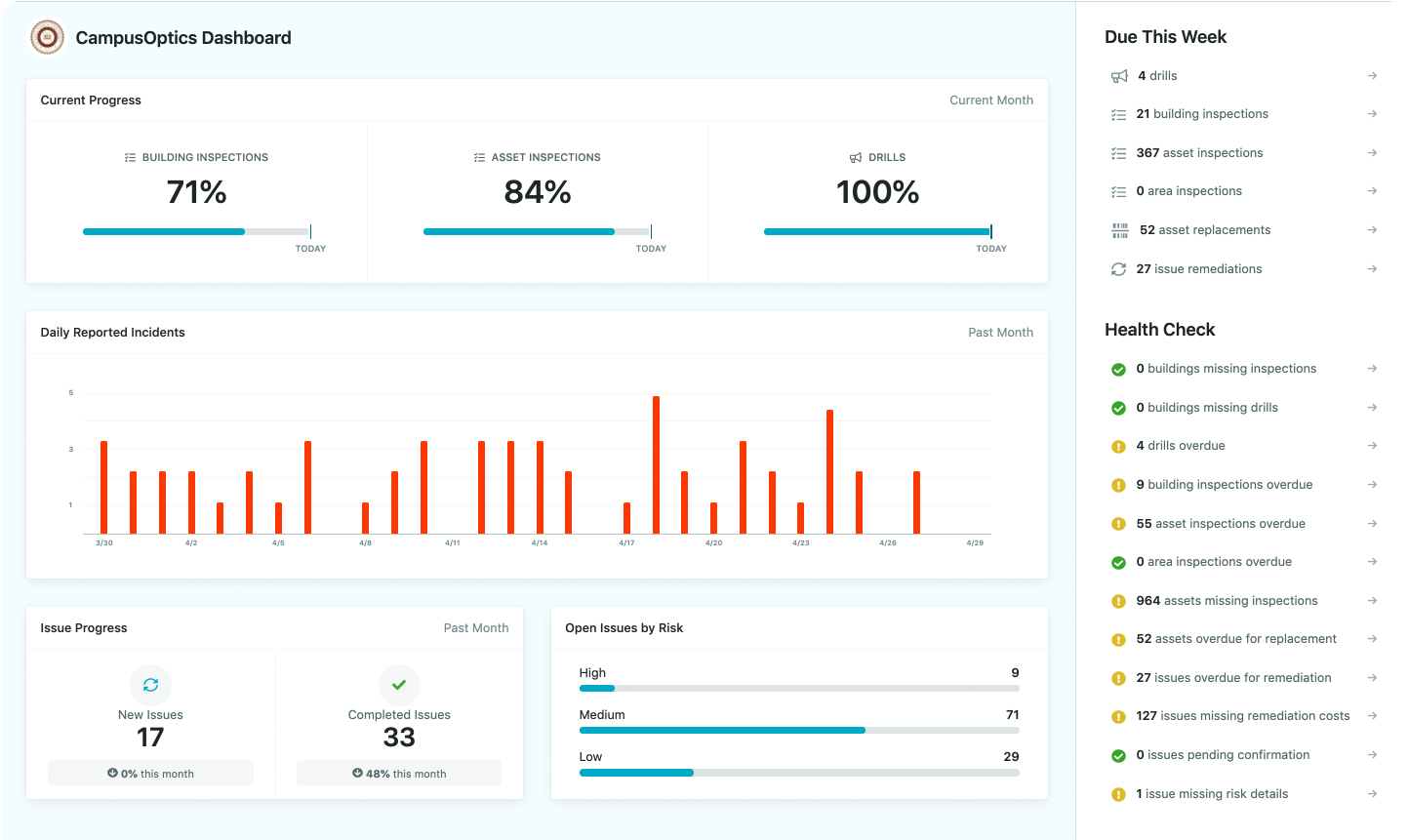

At CampusOptics, we’ve built our EHS platform specifically for colleges and universities, because higher ed doesn’t operate like other sectors. Campus safety involves dozens of departments, decentralized data, and constantly shifting compliance needs. We’ve seen firsthand how hard it is to maintain visibility when safety inspections are tracked in paper binders or chemical inventory lives in a spreadsheet nobody’s touched in six months.

Our platform gives safety professionals, facilities teams, and campus leadership a shared system to manage all aspects of EHS and Fire & Life Safety compliance. Whether you’re conducting lab inspections, managing hazardous waste, or prepping for an audit, we help you stay on track and respond faster when risks arise.

Here’s how we help campuses stay compliant and safer every day:

- Log and route safety issues instantly to the right teams

- Track inspections, permits, training, and assets from a single platform

- Maintain accurate chemical inventory and up-to-date SDS records

- Create and share emergency pre-plans for every building

- Monitor progress with real-time dashboards and compliance calendars

- Access everything on-the-go through our mobile app

We know that compliance isn’t just about passing audits – it’s about making campuses safer places to learn, work, and live. Our platform was designed with that mission in mind, and we’re proud to partner with institutions that share that goal.

Conclusion

Regulatory compliance isn’t something you can wing anymore. The rules are tighter, the expectations are higher, and the old ways of doing things just don’t cut it. EHS platforms give organizations the tools to move from scattered, reactive efforts to a more connected, proactive approach. Whether it’s keeping safety data current, automating reports, or spotting risks before they become problems, the right system can make life easier for the people doing the work – and give leadership the confidence that nothing’s slipping through the cracks.

At the end of the day, compliance isn’t just about staying out of trouble. It’s about building a workplace – or campus – where people feel safe and supported. The technology should work quietly in the background, helping teams focus on what really matters. That’s what strong EHS software does when it’s actually built with the user in mind.

FAQ

What is EHS software, and how is it different from a basic safety checklist?

EHS software goes beyond checklists. It brings all your safety, health, and environmental processes into one system, so you’re not juggling spreadsheets, forms, or shared drives. It tracks inspections, training, permits, chemical inventories, and more – all in one place.

Do small organizations really need a full EHS platform?

You don’t have to be a huge company to benefit. If you’re handling inspections, training, or hazardous materials – even with a small team – a platform can save time, reduce mistakes, and make it easier to respond when regulators come around.

Can EHS tools actually reduce the workload?

Yes. A lot of the daily tasks that take up time – logging incidents, tracking training, sending reminders – can be automated. That means your team spends less time chasing paperwork and more time focusing on actual safety.

What happens when regulations change?

Many EHS platforms include tools that monitor regulatory changes and flag when your current processes no longer match the latest rules. It’s a way to stay ahead without needing a full-time compliance researcher on staff.