EHS risk mitigation is critical to keep things running smoothly. It’s about catching problems before they blow up into expensive messes-think workplace injuries, environmental spills, or hefty fines. It protects your team, keeps you on the right side of the law, and makes sure your operations don’t grind to a halt. Plus, it’s not just about meeting the bare minimum for compliance. It’s about building a vibe where safety’s part of the everyday grind, which saves money, boosts morale, and keeps things sustainable. With regulations always changing and new risks popping up, a solid EHS plan keeps you ready for anything.

What Kinds of Risks Are We Talking About?

EHS risk management addresses a diverse range of hazards that can affect an organization’s operations, workforce, and surroundings. Understanding these risks is essential for developing effective mitigation strategies. The primary categories include:

- Physical Risks: Hazards from equipment, machinery, or workplace conditions that can lead to injuries or accidents. Examples include unguarded machinery or unsafe working surfaces.

- Chemical Risks: Exposure to hazardous substances that may cause health issues or environmental damage, such as improper handling of toxic chemicals.

- Biological Risks: Threats from pathogens or biological agents that can lead to illnesses, particularly in industries like healthcare or food processing.

- Ergonomic Risks: Issues related to workspace design or repetitive tasks that may cause musculoskeletal disorders, such as poorly designed workstations.

- Environmental Risks: Impacts from operations, such as pollution or resource depletion, that can harm ecosystems or violate regulations.

- Regulatory Risks: Non-compliance with laws or standards, which can result in fines, legal action, or reputational damage.

Each type requires tailored approaches to identification and control, ensuring comprehensive coverage across organizational activities.

EHS Risk Management for Colleges

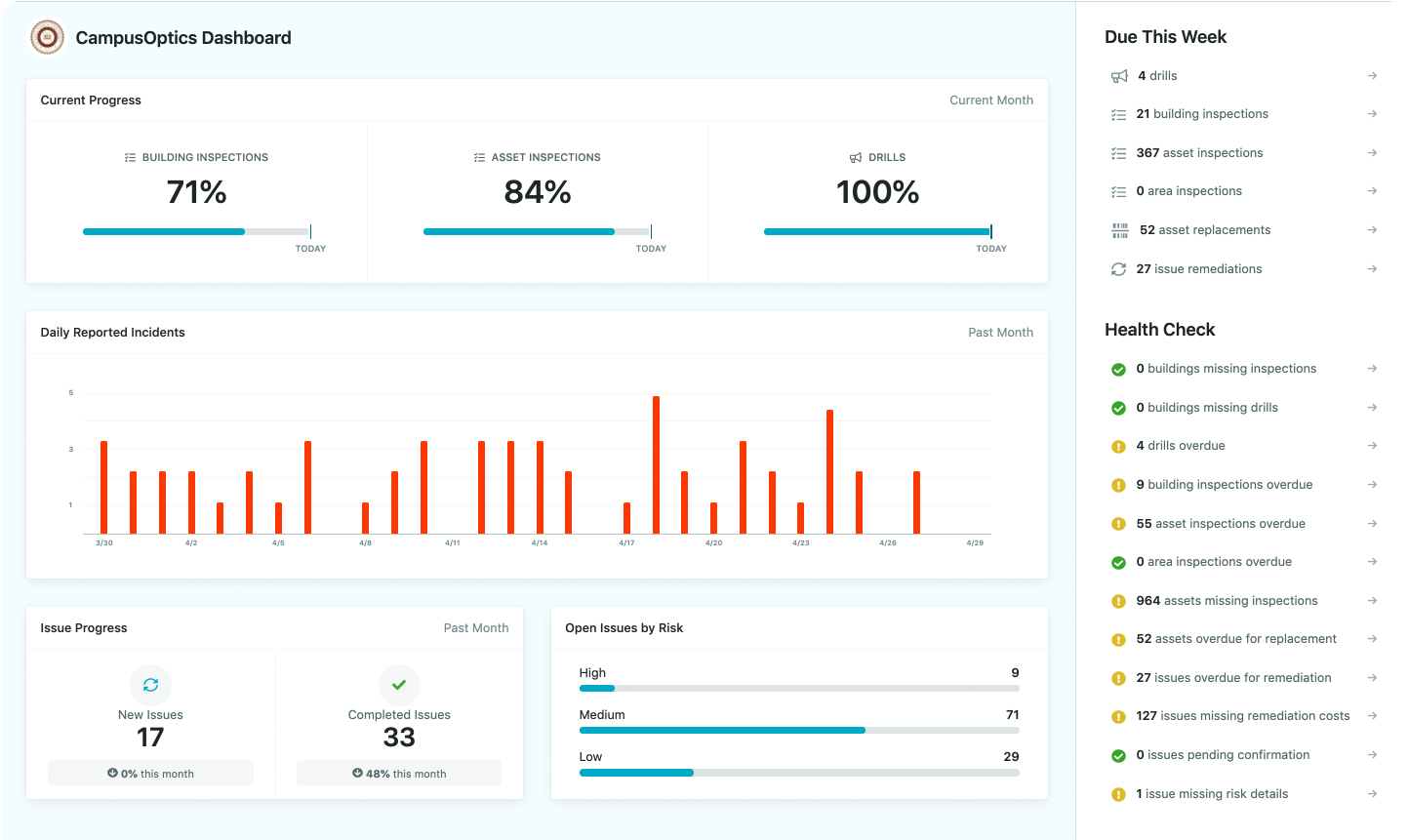

At CampusOptics, we understand the unique challenges that colleges and universities face in managing EHS risks within their complex and diverse operational environments. Our platform is designed to centralize safety, health, and environmental data, enabling institutions to track hazards, manage chemical inventories, and conduct inspections across multiple campus facilities. By streamlining compliance and fostering collaboration among safety teams, administrators, and emergency planners, we help ensure regulatory adherence while promoting a proactive approach to risk management. With mobile access and real-time data visualization, our tools empower campuses to address risks efficiently and maintain a safe, compliant academic environment.

EHS Risk Assessment Process

An EHS risk assessment is a formal process to identify potential hazards, evaluate their likelihood and severity, and determine appropriate controls. It is a critical step in prioritizing resources and ensuring that the most significant risks are addressed promptly. Assessments are conducted whenever new hazards are identified or operational changes introduce potential risks.

Steps in Conducting an EHS Risk Assessment

The EHS risk assessment process follows a structured methodology to ensure comprehensive hazard management. By systematically addressing risks, organizations can minimize incidents and enhance workplace safety. The process is iterative, requiring regular updates to remain effective in dynamic operational environments. Below is a detailed breakdown of the key steps involved:

1. Hazard Identification

This initial step focuses on recognizing anything that could cause harm to people, property, or processes. It requires a thorough examination of worksites, including physical inspections of equipment, facilities, and work areas. Engaging employees through interviews or surveys is critical, as their firsthand knowledge can reveal risks that may not be immediately visible, such as those in non-routine tasks like maintenance or cleaning. Reviewing operational procedures, incident reports, and near-miss logs also helps uncover potential hazards. For example, hazards might include unguarded machinery, improperly stored chemicals, or ergonomic issues from repetitive tasks. Comprehensive identification ensures no significant risk is overlooked, forming the foundation for subsequent steps.

2. Determining Potential Harm

Once hazards are identified, the next step is to assess who or what might be affected and how. This involves considering all stakeholders, including employees, contractors, visitors, and nearby communities, as well as environmental impacts. For instance, a chemical spill could expose workers to health risks and contaminate local water sources, affecting ecosystems and public health. This step requires mapping out the potential consequences of each hazard, such as injuries, property damage, or operational disruptions. It also involves analyzing the scope of impact, whether localized to a single worksite or extending to external communities. A thorough analysis ensures that all potential outcomes are accounted for in planning mitigation strategies.

3. Risk Evaluation and Prioritization

This step involves analyzing the likelihood and severity of each identified hazard to determine which risks require immediate attention. Risk scoring is a common method, where hazards are assigned numerical values based on their probability of occurrence and potential impact. For example, a hazard with a high likelihood but low severity, such as a minor trip hazard, may be prioritized differently than a low-likelihood but high-severity risk, like a chemical explosion. A risk scoring matrix can provide an objective framework for comparing risks across operations. This prioritization ensures that resources are allocated efficiently, focusing on hazards that pose the greatest threat to safety, compliance, or operational continuity.

4. Implementing Controls

After prioritizing risks, organizations must apply specific measures to mitigate them. Controls can include engineering solutions, such as installing machine guards or ventilation systems, administrative measures like safety protocols or training programs, and personal protective equipment as a last resort. The hierarchy of controls guides this process, prioritizing hazard elimination, followed by substitution, engineering controls, administrative measures, and finally protective equipment. Controls must be precise and tailored to the identified risks to ensure effectiveness. For instance, addressing a chemical exposure risk might involve substituting a hazardous substance with a safer alternative or implementing a lockout/tagout procedure for equipment maintenance. Clear documentation and communication of controls are essential for consistent application across the organization.

5. Monitoring and Review

The final step involves continuously evaluating the effectiveness of implemented controls and updating risk assessments to reflect changes in operations, regulations, or workplace conditions. Regular monitoring includes audits, inspections, and reviews of incident and near-miss data to assess whether controls are working as intended. For example, if a new piece of equipment is introduced, the assessment must be revisited to identify any new hazards. Feedback from employees and stakeholders also plays a critical role in identifying gaps or inefficiencies in controls. This iterative process ensures that risk management strategies remain relevant and effective, adapting to evolving operational and regulatory landscapes.

This systematic approach ensures that risks are managed proactively, reducing the likelihood of incidents and enhancing overall safety. By integrating these steps into daily operations, organizations can maintain a robust EHS framework that supports compliance and protects stakeholders.

Key Elements of Effective EHS Risk Management

Effective EHS risk management relies on four core components that work together to create a robust safety framework:

- Hazard Identification: The foundation of risk management, this involves systematically uncovering potential risks across operations, from equipment failures to environmental impacts.

- Risk Assessment: Evaluating the severity and likelihood of risks to prioritize resource allocation and mitigation efforts.

- Risk Mitigation: Implementing controls, such as redesigned processes or safety training, to minimize the impact of identified hazards.

- Monitoring and Review: Continuously tracking the effectiveness of controls and adjusting strategies to address new or evolving risks.

These elements ensure a comprehensive approach, integrating risk management into organizational processes and fostering a culture of safety.

Benefits of EHS Software

EHS software integrates data from various sources, providing a unified view of risks and compliance status. It supports real-time monitoring, automated reporting, and predictive analytics, allowing organizations to address hazards swiftly. By centralizing data, software eliminates silos, ensuring that all departments have access to critical information. This integration enhances collaboration, improves decision-making, and aligns risk management with broader operational goals.

Challenges in Technology Adoption

Despite its benefits, adopting technology for EHS risk management can face obstacles. Data silos, where information is fragmented across departments, hinder comprehensive risk visibility. Resistance to change from employees or management can slow implementation. Additionally, integrating new systems with existing processes requires careful planning to avoid disruptions. Organizations can address these challenges by investing in user-friendly platforms and providing training to ensure smooth adoption.

Challenges in Integrated EHS Risk Management

Integrated EHS risk management, which aligns safety, health, and environmental strategies across an organization, faces several hurdles. Fragmented data systems create blind spots, making it difficult to assess risks holistically. Lack of alignment between departments can lead to inconsistent risk management practices. Cultural resistance to adopting new processes or technologies can further complicate efforts. Overcoming these challenges requires centralized systems, clear communication, and leadership commitment to embedding risk management into organizational culture.

Strategies for Proactive EHS Risk Management

A proactive approach to EHS risk management involves anticipating hazards rather than reacting to incidents. This requires fostering a culture where employees are encouraged to report near-misses and hazards without fear of reprisal. Regular training and clear communication of safety policies help embed risk awareness into daily operations.

Implementing Effective Controls

Controls are critical to reducing risks. These can include engineering solutions, such as machine guards, administrative measures like safety protocols, or personal protective equipment. The hierarchy of controls prioritizes eliminating hazards where possible, followed by substitution, engineering, and administrative measures, with protective equipment as a last resort.

Continuous Improvement

Continuous improvement involves regularly reviewing risk management processes to ensure they remain effective. This includes analyzing incident data, updating risk assessments, and refining controls based on new information or operational changes. Regular audits and employee feedback help identify areas for enhancement.

Compliance and EHS Risk Management

Compliance with regulatory standards is a critical aspect of EHS risk management. Non-compliance can result in fines, legal action, and reputational damage. By integrating compliance into risk management strategies, organizations ensure they meet legal requirements while addressing broader safety and environmental goals.

Tools for Compliance Management

EHS software plays a key role in compliance management by automating reporting and tracking regulatory requirements. These tools provide dashboards to monitor compliance status, generate reports for regulatory bodies, and ensure timely updates to policies as regulations change. This reduces the risk of violations and streamlines audit processes.

Wrapping It Up

EHS risk management isn’t just a corporate buzzword-it’s about keeping people safe, the environment clean, and your organization out of trouble. By spotting risks early, assessing them smartly, and using tools like software or sensors, you can stay ahead of problems. Sure, there are hurdles-data messes, resistance to change-but with a proactive mindset and the right tech, you can build a safer, stronger workplace. It’s not perfect, but it’s worth it.

FAQs

What’s EHS risk management all about?

It’s finding, sizing up, and tackling risks to keep your workplace safe and compliant with environmental and health rules.

What kinds of risks should I worry about?

You’ve got physical stuff (like broken machines), chemicals, germs, bad ergonomics, environmental damage, stress, and regulatory slip-ups.

How does a risk assessment work?

Spot hazards, figure out who they could hurt, rank them by likelihood and impact, put fixes in place, and keep checking if they’re working.

Why’s tech such a big deal for this?

Tools like sensors and software give you real-time data, predict problems, and make compliance way less painful.

What’s the hardest part of EHS risk management?

Getting everyone aligned, dealing with scattered data, and convincing people to embrace new tools or processes.

How do I make this proactive instead of reactive?

Get your team talking about risks, train them regularly, and keep tweaking your approach based on what you learn.