Chemical inventory tracking is a systematic process for monitoring, recording, and managing chemicals used, stored, or disposed of within an organization. It involves maintaining detailed records of chemical substances, including their identity, quantity, location, and associated safety information. This process is critical in industries such as laboratories, manufacturing, oil and gas, and water treatment, where chemicals are integral to operations. Effective tracking ensures compliance with regulations, enhances workplace safety, and optimizes resource management. This article explores the core components, benefits, and modern approaches to chemical inventory tracking, providing a clear understanding of its role in operational efficiency.

Industry Applications of Chemical Inventory Tracking

Chemical inventory tracking is indispensable across a range of industries, each facing distinct challenges in managing hazardous materials. These systems provide the structure needed to maintain safety, ensure regulatory compliance, and optimize operational workflows by addressing the specific needs of each sector.

Laboratories and Research Facilities

In laboratory settings, where precision and safety are paramount, chemical inventory tracking ensures researchers have access to necessary substances while adhering to strict safety protocols. These systems meticulously document small quantities of diverse chemicals, capturing details like concentration, storage conditions, and hazard classifications. By maintaining accurate records, they prevent cross-contamination and ensure compliance with regulations such as those set by OSHA or institutional safety boards. Additionally, tracking expiration dates and usage patterns helps labs avoid using degraded chemicals, reducing the risk of experimental errors or hazardous reactions.

Manufacturing and Industrial Plants

Manufacturing facilities depend on large volumes of chemicals to drive production processes, from raw material synthesis to product finishing. Inventory tracking systems are critical for monitoring stock levels to avoid production delays caused by shortages. These systems also ensure hazardous materials are stored according to safety guidelines, preventing dangerous interactions, such as storing flammable liquids near oxidizers. By integrating real-time data and location tracking, they minimize risks to workers and equipment, while also supporting efficient inventory management to reduce waste and streamline procurement cycles.

Oil and Gas Sector

The oil and gas industry relies heavily on specialized chemicals, such as drilling fluids, corrosion inhibitors, and mercaptans, to maintain operational continuity. Chemical inventory tracking systems ensure these materials are readily available and stored in compliance with stringent safety standards. They provide detailed records of chemical quantities and locations, reducing downtime caused by supply shortages. Furthermore, these systems support emergency preparedness by offering immediate access to safety data, enabling rapid response to incidents like spills or leaks, which is critical in high-risk environments.

Water Treatment Operations

Water treatment facilities manage chemicals like chlorine, coagulants, and pH adjusters to ensure safe and effective water processing. Inventory tracking systems centralize data on these substances, ensuring proper storage and usage to meet regulatory requirements, such as those from the EPA. By tracking quantities and monitoring usage patterns, these systems prevent overstocking or shortages, maintaining operational efficiency. They also document disposal processes for chemical waste, ensuring compliance with environmental regulations and supporting sustainable practices in water treatment operations.

Key Features to Consider in a Tracking System

When selecting a chemical inventory tracking system, organizations should prioritize features that align with their operational needs and compliance requirements. Essential features include:

- Real-Time Data Access: Systems should provide up-to-date information on stock levels, locations, and usage, enabling quick decision-making.

- Mobile Accessibility: Mobile support allows users to update or access inventory data from remote locations, improving flexibility.

- Customizable Reporting: Flexible reporting tools generate tailored reports for audits, safety inspections, or operational analysis.

- Integration Capabilities: Compatibility with enterprise resource planning (ERP) systems or safety databases ensures seamless workflows across departments.

Specialized Tools for Educational Institutions

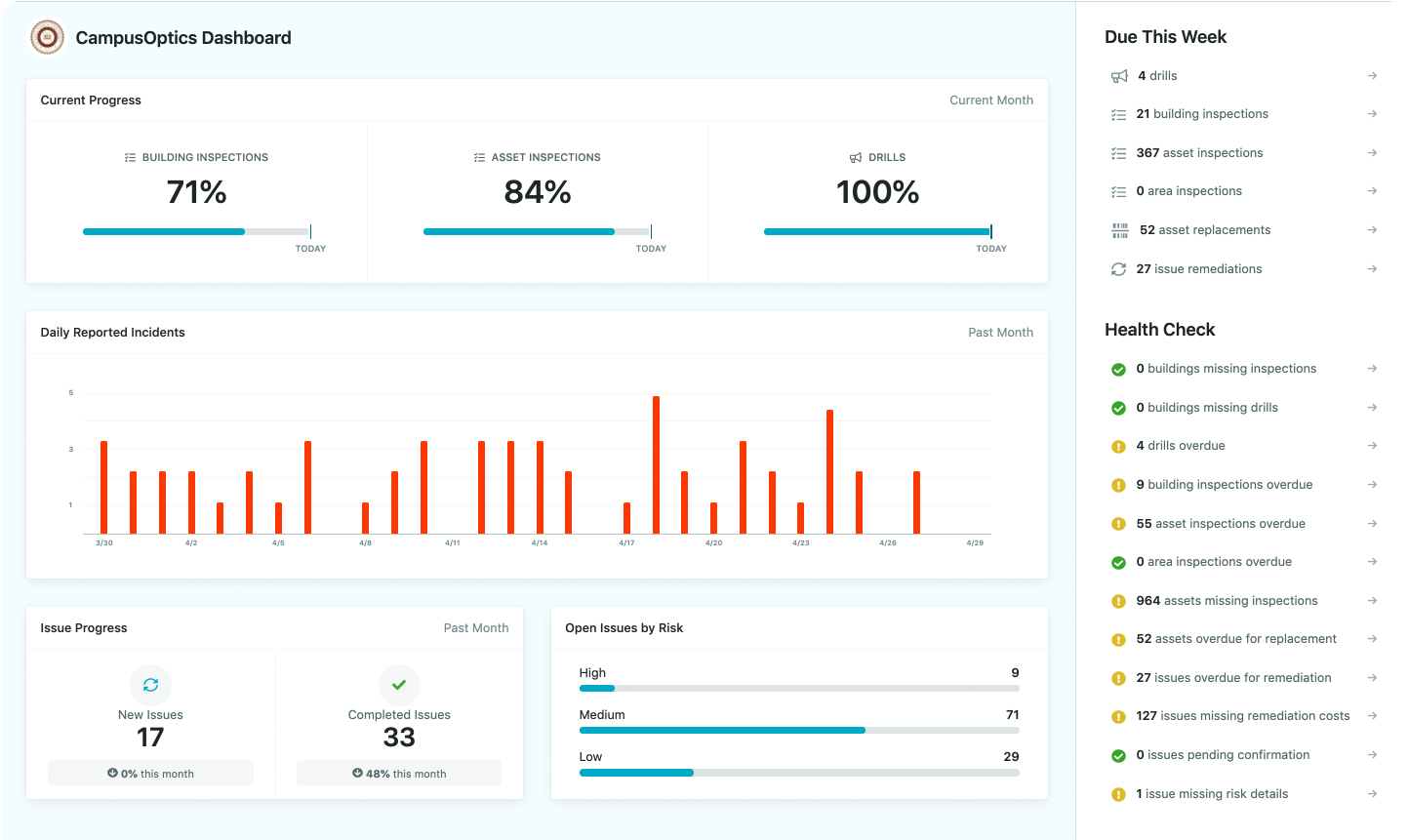

At CampusOptics, we understand that chemical inventory tracking in higher education requires more than just logging quantities and locations – it demands a comprehensive approach to environmental health and safety (EH&S). Our platform is designed specifically for universities and colleges, integrating chemical inventory management with hazardous waste tracking, safety asset monitoring, and emergency planning. This unified system helps us ensure compliance, reduce risks, and promote collaboration across campus teams, from research labs to maintenance departments, in a way that fits the unique needs of sprawling academic environments.

We’ve built our solution with mobility in mind, knowing that EH&S professionals are rarely at their desks. Our iOS and Android app allows us to scan barcodes or QR codes on chemical containers, access safety data sheets instantly, and attach photos directly from the field. Our visualization tools also simplify tracking by mapping chemical locations campus-wide, using either imported data or coordinates logged on-site. With features like unlimited user access, customizable permissions, and SSO integration, we ensure that lab technicians, risk managers, and safety officers have the right information at the right time. This streamlined approach helps us keep chemical management aligned with audits and emergency protocols, making campus safety more manageable and effective.

Core Components of Chemical Inventory Tracking

Chemical inventory tracking is built on several key elements that collectively create a robust management system. These components ensure that organizations maintain accurate and accessible records, reducing risks associated with chemical handling.

Chemical Identification and Documentation

The foundation of any chemical inventory system is the accurate identification of substances. This includes recording the chemical name, Chemical Abstracts Service (CAS) number, and associated safety data sheets (SDS). These records provide essential details about each chemical’s properties, hazards, and handling requirements. By maintaining a centralized database of this information, organizations can quickly reference critical data during routine operations or emergencies.

Quantity and Storage Location Tracking

Tracking the quantity and storage location of chemicals is essential for operational control. This involves documenting the exact amount of each substance, its container size, and its precise location within a facility. For organizations with multiple sites, systems must support multi-location tracking to ensure visibility across all facilities. Accurate location data prevents misplacement and ensures that chemicals are stored appropriately to avoid hazardous interactions.

Hazard and Safety Information Management

Chemical inventory systems must include detailed hazard classifications, such as flammability, toxicity, or corrosiveness. These classifications, often linked to SDS, guide safe handling practices and inform emergency response protocols. By integrating hazard information into the tracking system, organizations can ensure that employees have immediate access to safety guidelines, reducing the risk of accidents.

Expiration Date Monitoring

Chemicals have finite shelf lives, and using expired substances can lead to inefficiencies or safety hazards. A tracking system monitors expiration dates, alerting managers when chemicals are nearing the end of their usable life. This proactive approach minimizes waste and prevents the use of degraded materials that could pose risks.

Supplier and Procurement Details

Maintaining records of chemical suppliers, including contact information, catalog numbers, and lot numbers, streamlines procurement processes. This component ensures that organizations can efficiently reorder supplies and verify the authenticity of received chemicals. Advanced systems may allow suppliers to update product details directly, improving communication and data accuracy.

Disposal and Waste Management

Proper disposal of expired or waste chemicals is a critical aspect of inventory tracking. Systems must document how chemicals are disposed of, ensuring compliance with environmental regulations. This includes tracking disposal methods, dates, and responsible parties to maintain an audit trail for regulatory purposes.

Benefits of Effective Chemical Inventory Tracking

Implementing a robust chemical inventory tracking system delivers measurable advantages across safety, compliance, and operational efficiency. The following benefits highlight its importance:

- Improved Safety: Accurate tracking prevents hazardous mix-ups by ensuring proper storage and immediate access to safety data, reducing the risk of accidents like chemical reactions or exposures.

- Regulatory Compliance: Systems provide real-time data for inspections, ensuring adherence to standards set by OSHA, EPA, or other authorities, minimizing fines or shutdowns.

- Cost Efficiency: By preventing overstocking and monitoring expiration dates, organizations reduce waste and optimize procurement, leading to financial savings.

- Enhanced Emergency Response: Detailed inventory records enable responders to quickly identify chemicals involved in incidents, improving response times and safety outcomes.

Modern Approaches to Chemical Inventory Tracking

Advancements in technology have transformed chemical inventory tracking from manual, error-prone methods to sophisticated digital systems. These modern tools enhance accuracy, accessibility, and integration with other operational systems.

Digital and Cloud-Based Platforms

Modern tracking systems leverage cloud-based platforms for real-time updates and centralized data storage. These systems allow authorized users to access inventory information from any device, whether on-site or remotely. Cloud solutions also ensure data security and facilitate collaboration across teams and locations.

Barcode and RFID Integration

Barcode and RFID scanning streamline data entry and updates. By scanning a chemical container, users can instantly record its details, such as quantity, location, or usage. This reduces manual errors and speeds up inventory management tasks, particularly in large facilities.

Automated Alerts and Notifications

Digital systems often include automated alerts for critical events, such as low stock levels or approaching expiration dates. These notifications enable proactive management, ensuring that chemicals are reordered or disposed of before issues arise. Alerts also support compliance by reminding managers of upcoming inspections or reporting requirements.

Integration with Safety and Compliance Databases

Many tracking systems integrate with external databases, such as SDS repositories, to provide instant access to safety information. This integration ensures that employees can retrieve handling instructions or hazard details without searching through physical files, improving response times in critical situations.

Challenges of Inadequate Chemical Inventory Tracking

Without a proper tracking system, organizations face significant risks. Manual methods, such as spreadsheets or paper logs, are prone to errors like incomplete records or misplaced containers. These mistakes can lead to unsafe storage practices, increasing the likelihood of accidents or regulatory violations. Inadequate tracking may also result in overstocking, leading to waste, or shortages, disrupting operations. In emergencies, the lack of accurate data can delay response efforts, exacerbating risks to personnel and facilities.

Best Practices for Implementation

To maximize the effectiveness of a chemical inventory tracking system, organizations should adopt structured implementation strategies.

Initial Setup and Data Entry

Begin by conducting a comprehensive inventory of all chemicals, documenting their details accurately. Use barcode or RFID tags to streamline future updates. Ensure that all data, including SDS, is entered into the system to create a reliable baseline.

Staff Training and Engagement

Train employees on using the tracking system, emphasizing the importance of accurate data entry and adherence to safety protocols. Regular training sessions reinforce proper usage and ensure that new staff are familiar with the system.

Regular Audits and Updates

Conduct periodic audits to verify inventory accuracy and compliance with regulations. Update the system with any changes in chemical stock, locations, or supplier details to maintain data integrity.

System Maintenance and Scalability

Choose a system that can scale with organizational growth, supporting additional locations or increased chemical volumes. Regular software updates ensure compatibility with evolving regulatory requirements and technological advancements.

Conclusion

Chemical inventory tracking is a critical process for organizations handling hazardous materials, ensuring safety, compliance, and operational efficiency across industries like laboratories, manufacturing, oil and gas, and water treatment. By systematically documenting chemical identities, quantities, locations, and safety data, these systems reduce risks of accidents, streamline procurement, and support rapid emergency responses. Transitioning from manual methods to digital solutions with real-time data, barcode scanning, and automated alerts transforms how we manage chemicals, minimizing errors and waste. Implementing robust tracking practices, supported by regular audits and staff training, is essential to meet regulatory standards and maintain a safe working environment. Ultimately, effective chemical inventory tracking empowers organizations to operate securely and efficiently, safeguarding both personnel and resources.

FAQs

What is chemical inventory tracking?

Chemical inventory tracking is the process of monitoring, recording, and managing chemicals within an organization, including their identity, quantity, location, and safety information.

Why is chemical inventory tracking important?

It ensures workplace safety, regulatory compliance, operational efficiency, and effective emergency response by maintaining accurate records of chemical substances.

What information is tracked in a chemical inventory system?

Typical information includes chemical names, CAS numbers, quantities, storage locations, hazard classifications, expiration dates, and supplier details.

How do digital tools improve chemical inventory tracking?

Digital tools, such as cloud-based platforms and barcode scanning, enable real-time updates, reduce errors, and provide accessible data for safety and compliance.

Which industries benefit from chemical inventory tracking?

Industries like laboratories, manufacturing, oil and gas, and water treatment rely on tracking systems to manage chemicals safely and efficiently.

How does chemical inventory tracking support emergency response?

Accurate inventory data allows responders to quickly identify chemicals involved in incidents, enabling faster and safer response strategies.

What are the risks of not using a chemical inventory tracking system?

Inadequate tracking can lead to errors, unsafe storage, regulatory violations, operational disruptions, and delayed emergency responses.